TPEC’s ROLE

TPEC’s ROLE

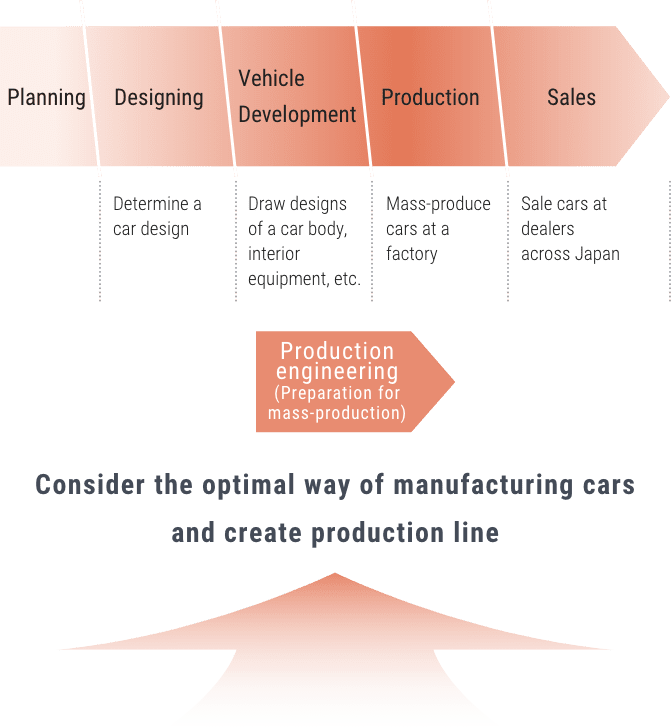

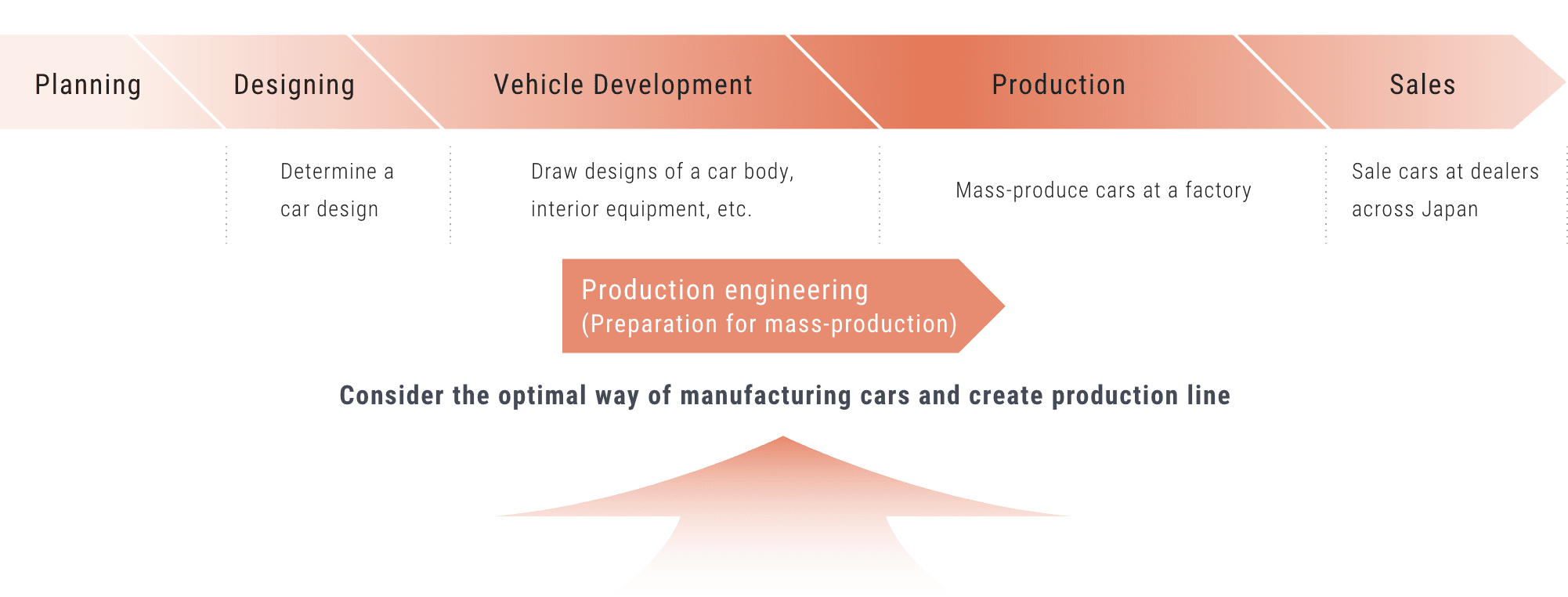

Process until cars are sold

Technology

Development

Digital Engineering &

Field Engineering Support

Digital

Engineering

Convert real physical events into digital data

Field

Engineering

Apply digital data in real physical life

Support each of TOYOTA’s auto manufacturing process with focusing

on production engineering (preparation for mass-production) with our digital engineering.

We will realize “ ever-better cars creation.”

TPEC’s ROLE

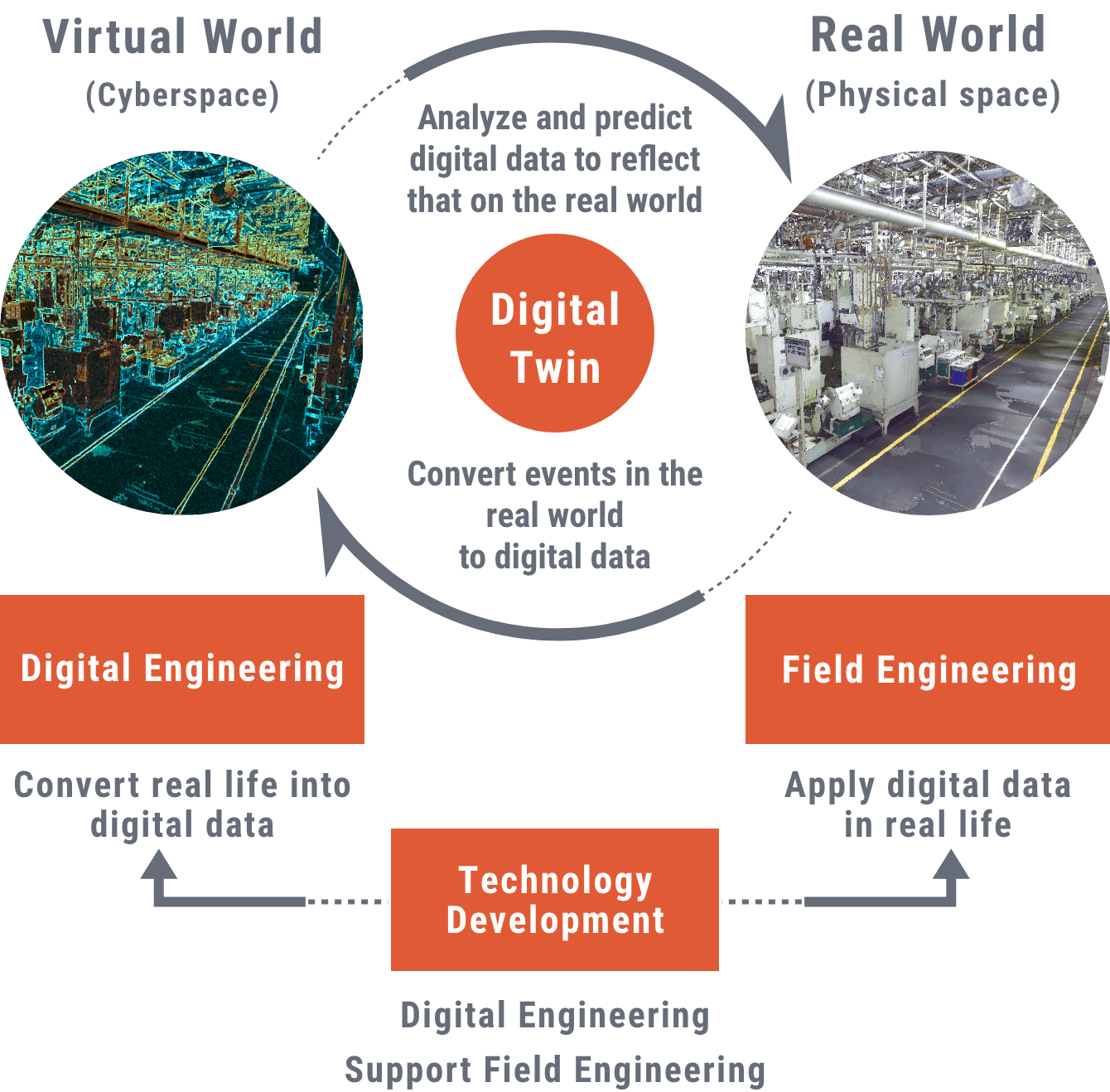

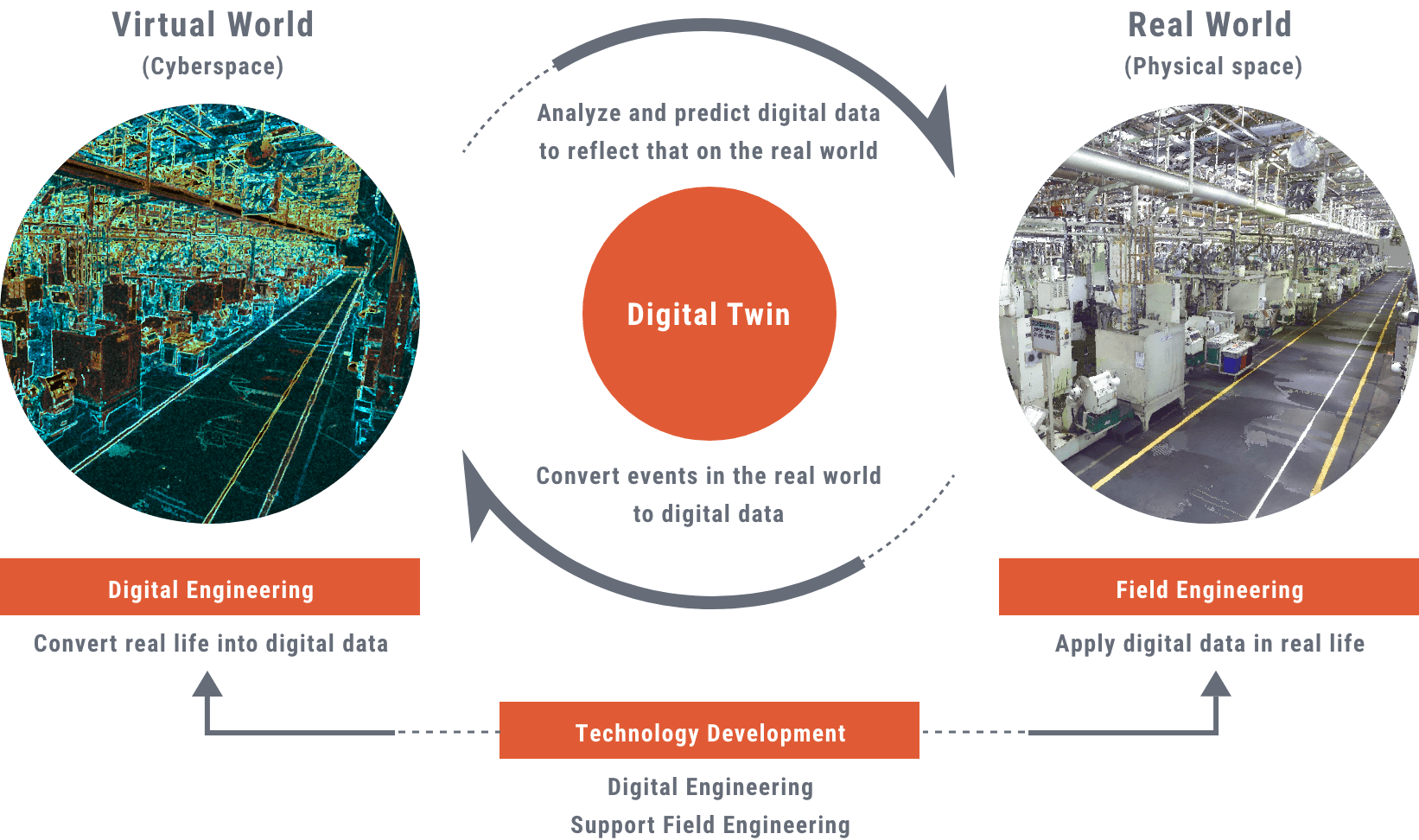

We will promote Digital Twin in collaboration between technology, digital engineering and field engineering fields.

We will realize the digital twin of cyber space and physical space through “expansion of digital technology in manufacturing”.

DIGITAL ENGINEERING Convert real life into digital data

In order to solve technological problems in automobile production engineering (mass-production preparation), we collect information in the real space (or factory) through IoT, etc., and reproduce the real space as a digital factory in cyber (or virtual) space based on transmitted data.

The realization of digital twin will enable us to simulate future changes in a factory with a digital factory and prepare for possible changes in the physical space. This is also one of TPEC’s business missions.

We will contribute to the prevention of possible problems with reproducing a real factory (or a product line) on the virtual space and carrying out various simulations.