TPEC’s ROLE

Technology Development FieldDevelopment of next-generation technology

Our Mission

Developing new tools to realize the digital twin

We are also working on experiments and demonstrations of new technologies to realize a digital twin. In addition, we are involved in the development, testing, and demonstration of technologies that have not yet been established and are responsible for providing technology in the fields of digital engineering and field engineering, respectively, for the betterment of manufacturing.

Our Direction

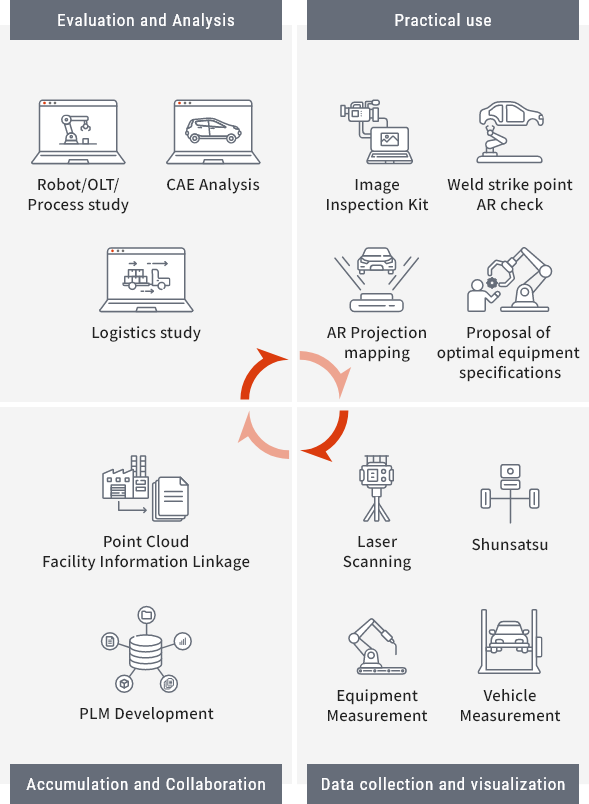

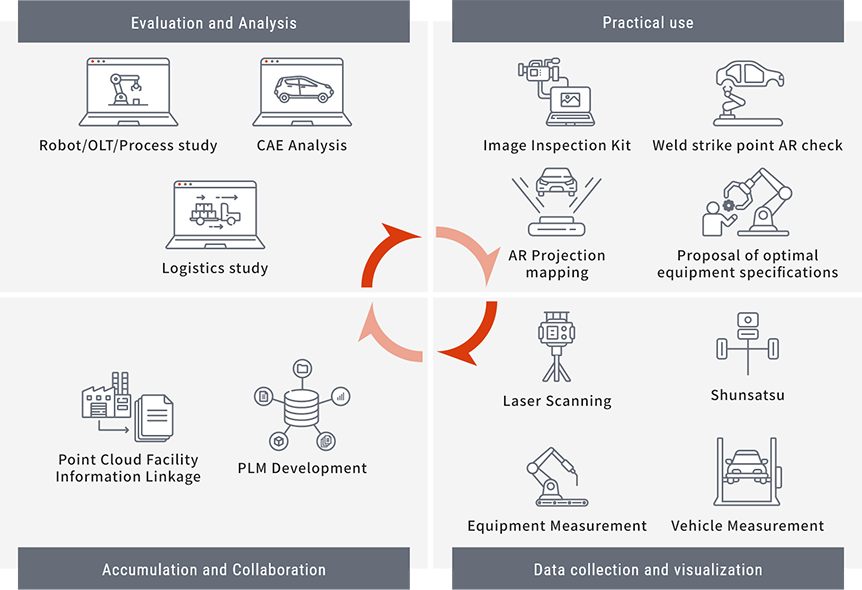

To establish a digital twin, TPEC will promote the development of TPEC's original technologies in the four phases of data collection, accumulation, quality assessment, and utilization.

Our Capabilities

IoT

We analyze inspection image data from equipment to automate the visual inspection process.

Development of business systems using cloud services

We develop business systems using public clouds such as Microsoft Azure and Amazon Web Service in order to speed up development, reduce costs, and improve scalability.

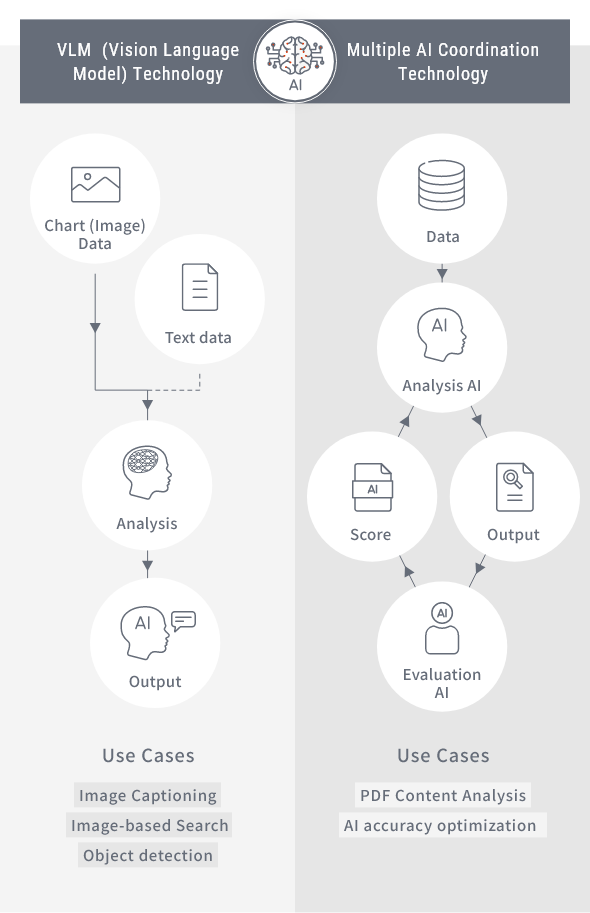

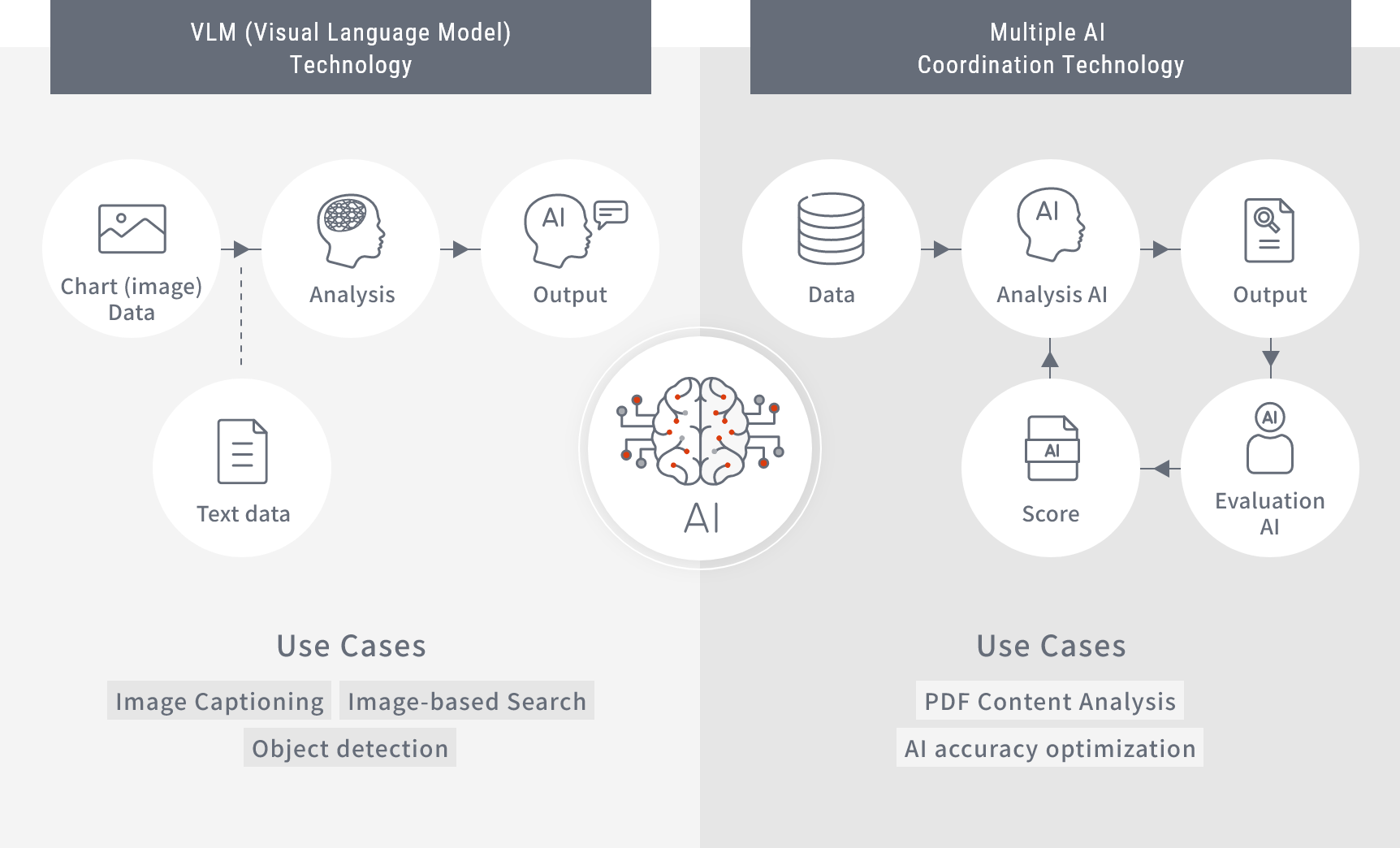

AI Solutions for the Manufacturing Industry

We develop AI and generative AI tools tailored to the operations and technologies of the manufacturing industry.

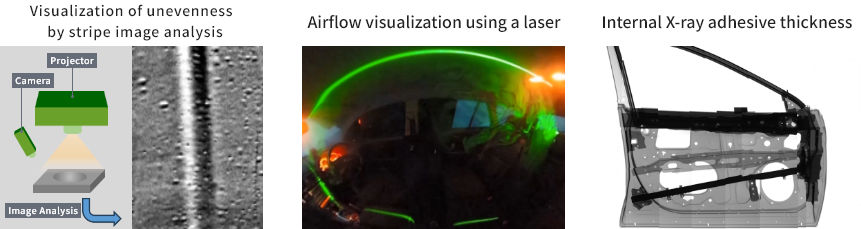

Visualization technology

We have developed special technology to visualize stresses, air currents, and internal material thicknesses, which originally cannot be seen as they are, using paint, lasers, and X-rays.

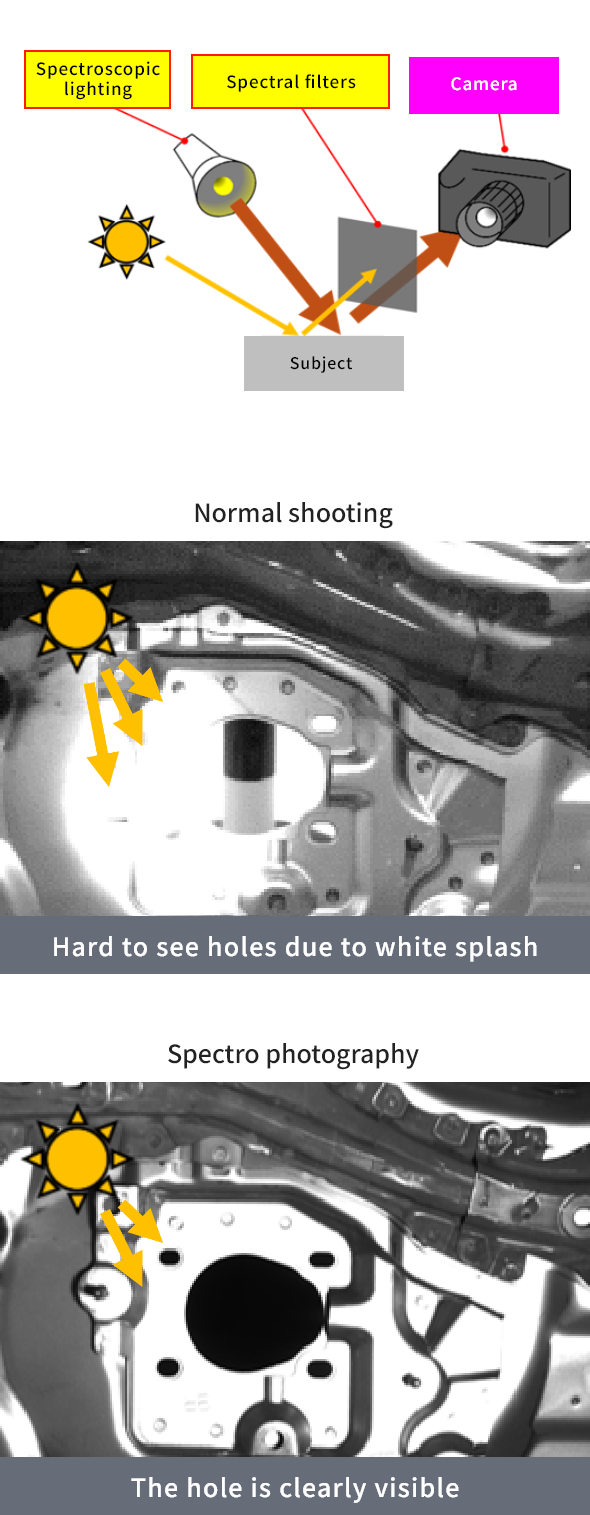

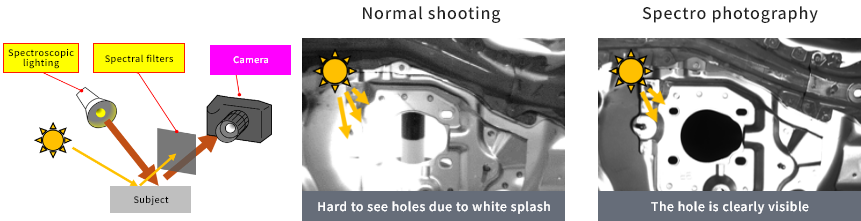

Spectroscopic technology

We are developing a technology to capture only specific light wavelengths. Noise (unwanted light) is greatly reduced, and necessary information, such as enhancement of specific areas, becomes clearer.

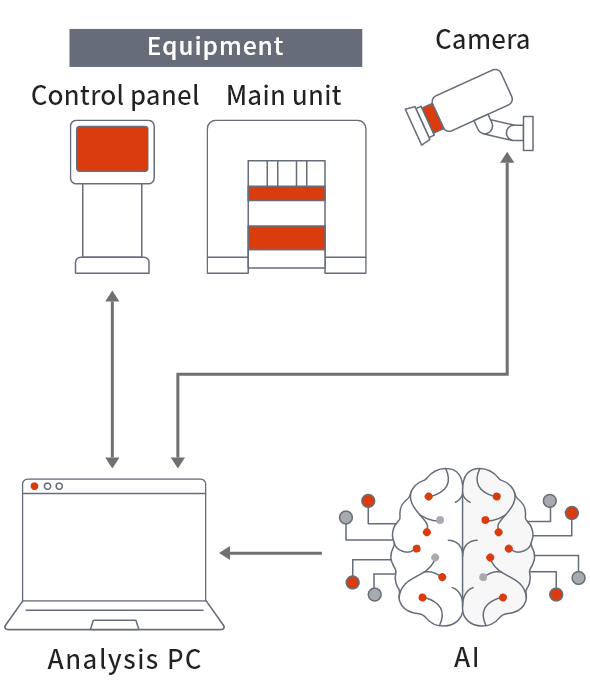

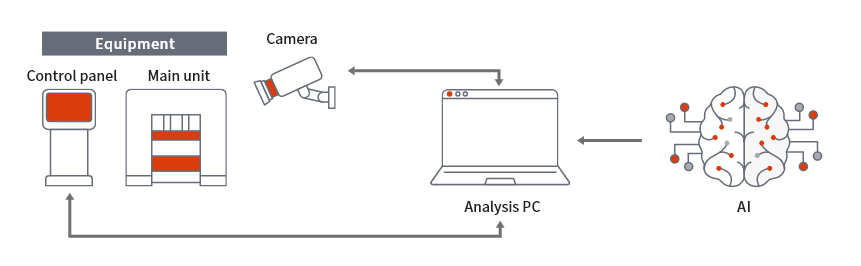

Image inspection system

The system enables easy start-up of image inspection by realizing a sequence of non-programmed processes, such as "camera shooting in accordance with equipment operation timing ⇒ AI processing of the acquired images".

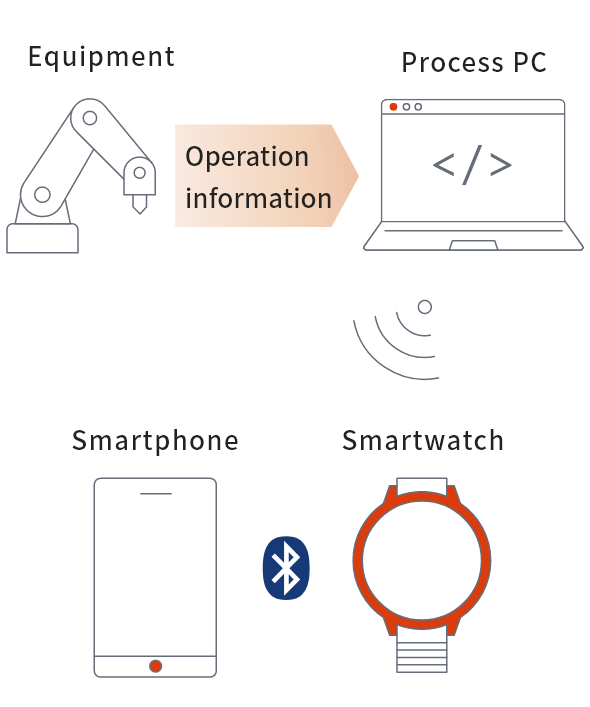

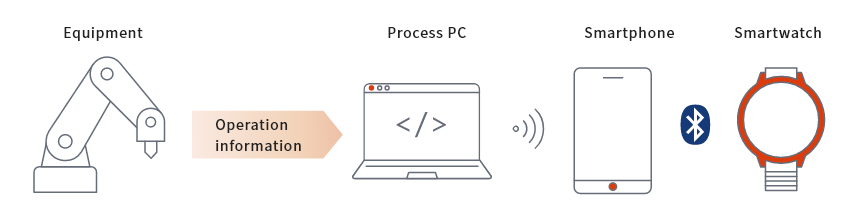

Real time display of equipment operation status

By displaying equipment operating status in real time on a smart device, information can be checked from anywhere in the plant.

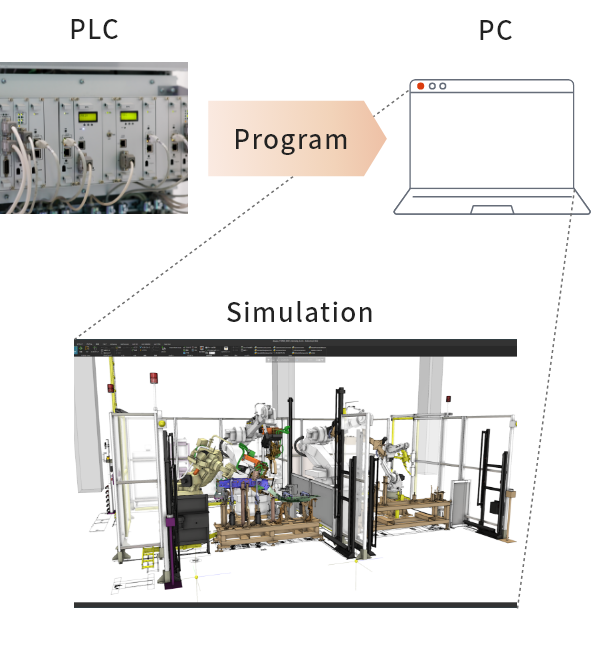

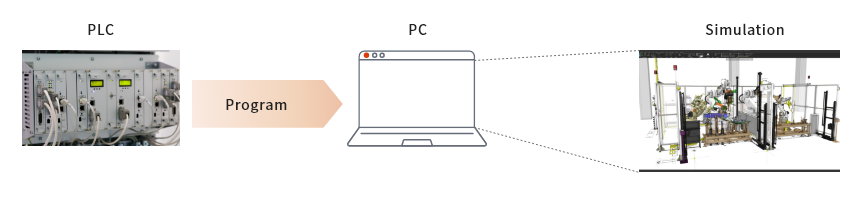

Simulating PLC (Facility Controllers)

By simulating on data how the actual equipment operates under PLC control, circuit evaluation can be performed even without the actual equipment, and the degree of completion can be improved at an early stage.