TPEC’s ROLE

Digital Engineering Field Measurement Technique

Our Mission

Digitalizing everything in a factory

Measurement has two purposes, one is product quality inspection and the other is digitalizing factories and facilities. For example, we digitalize a factory with a laser scanner, etc. for layout changes of existing factories and facilities. That enables to plan exact and safe construction as well as layout study, which contributes to reduction of redos and cost & time savings.

Our Direction

Digitalizing factories, facilities and jigs

We reproduce actual-site situations with accuracy to use them for construction study and quality analysis.

- Saving production preparation time

- Study on facility introduction in changing over to new models

- Improvement in study accuracy& digital study accuracy

- Accurate reproduction of actual products at actual sites

Our capabilities

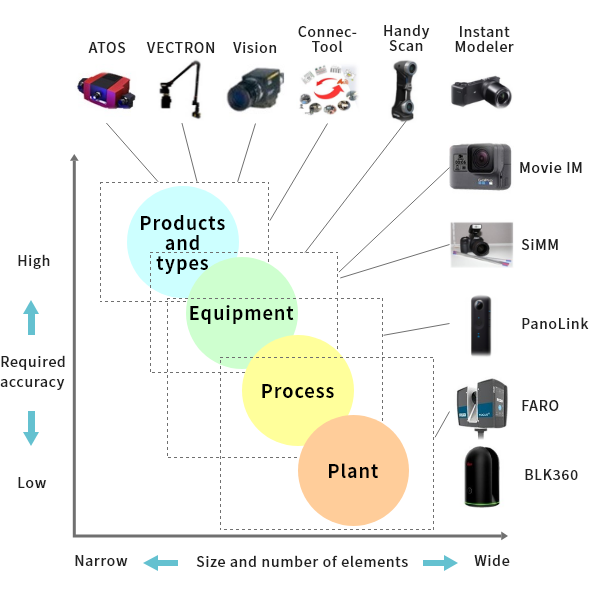

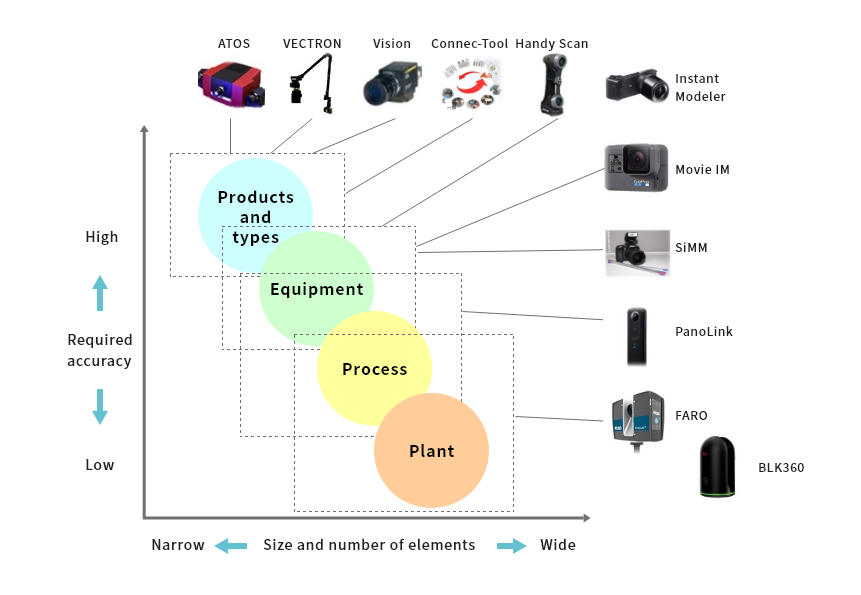

Measuring instruments and their scope

From large-scale factory measurements to high-precision product measurements, we select the equipment that best suits the scale of measurement and the required accuracy, and provide data that meets your objectives.

3D Measurement of Factories and Facilities

We measure and digitalize a large scale automobile factory with a laser scanner, etc. to use the obtained data in facility layout study, construction plan, etc. We use the measured data for various studies leading to high-accuracy study.

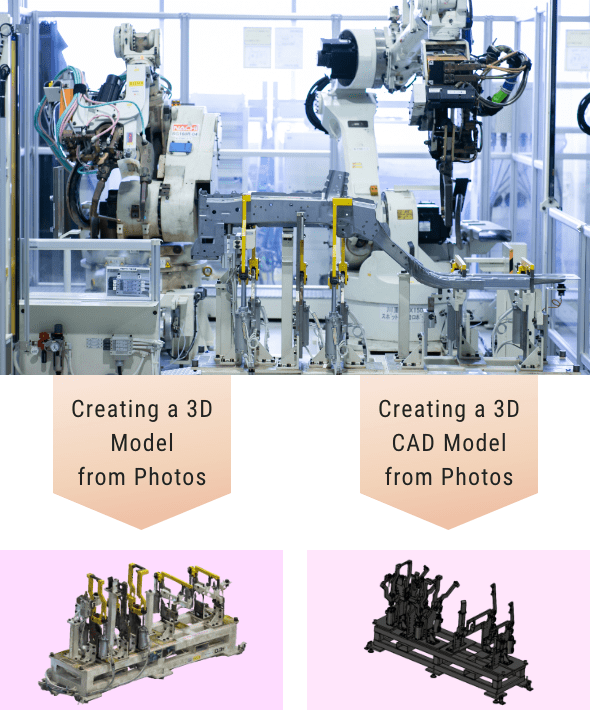

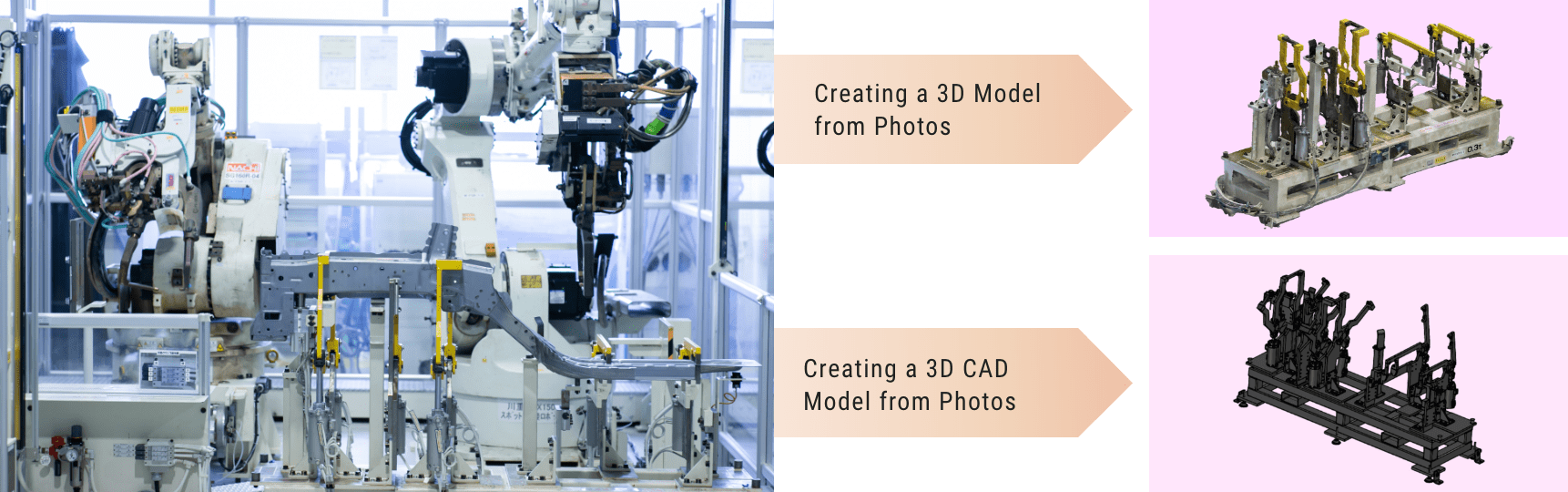

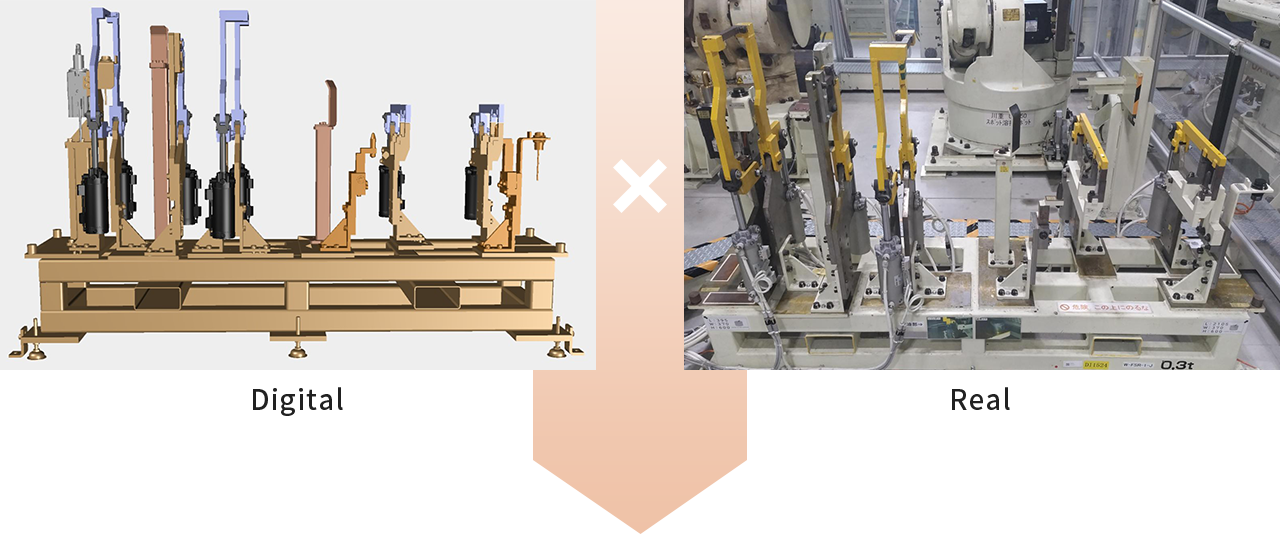

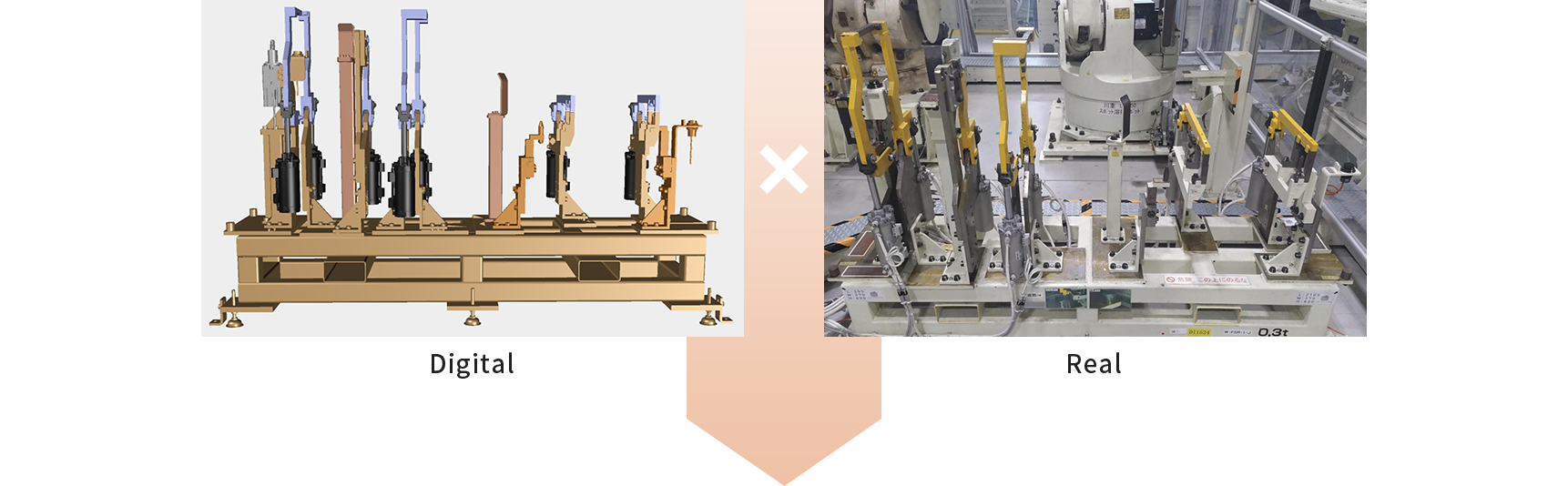

3D Measurements of Facilities and Jigs

For small objects as jigs to fix workpieces (or parts), we select modeling methods according to them, between using handy scanners, ARM measuring instrument and small cameras, which enables us to provide suitable data for customers’ needs.

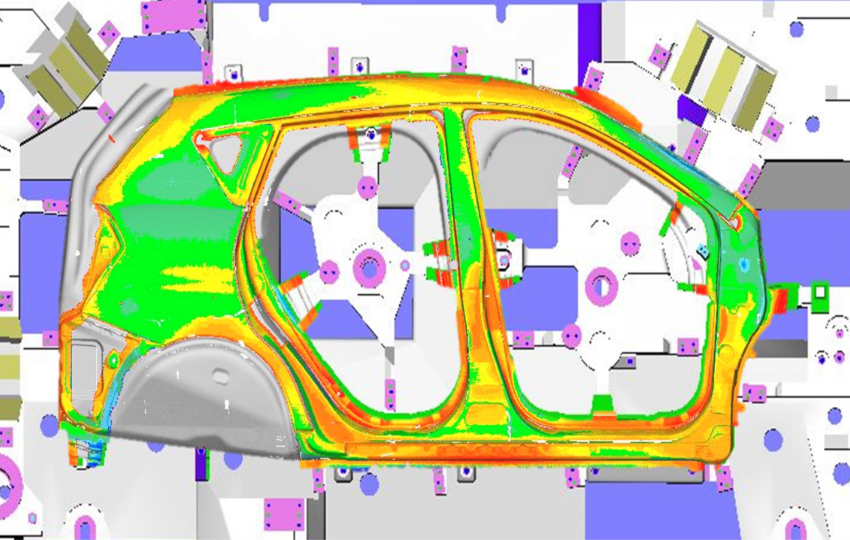

3D Measurement of Vehicles and Molds

As high accuracy is required for automobile parts, it is available to perform highly accurate measurement to meet customers’ needs. Measured data is used for mold repeat production and early detection of problems.

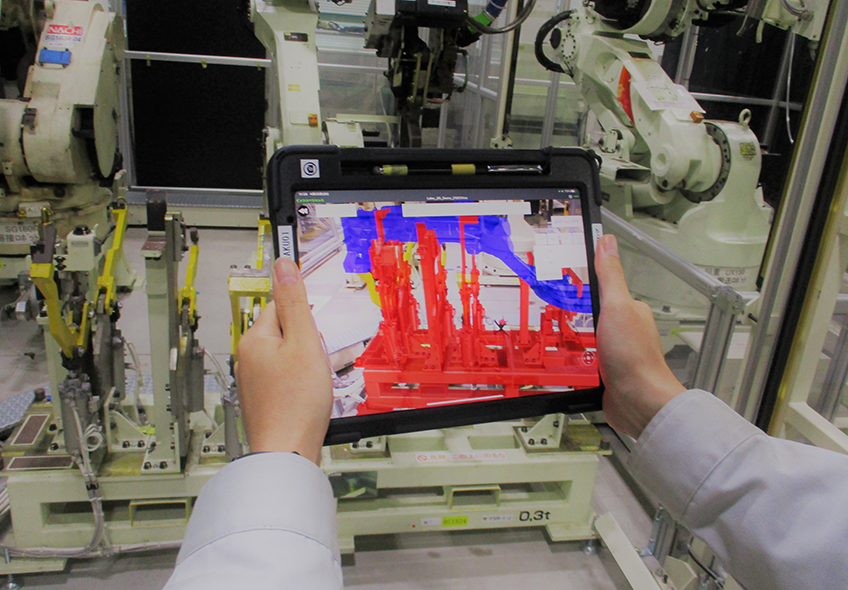

AR contents

Comparisons between the actual (real) product and CAD or measurement data (digital) can be easily made using a tablet, contributing to more efficient checking work on site.

Mobile terminal(Confirmation work)

・Possible to efficiently check if the jig is as designed.

・By displaying CAD data, it is possible to efficiently check the interference of jigs even when no parts are available.

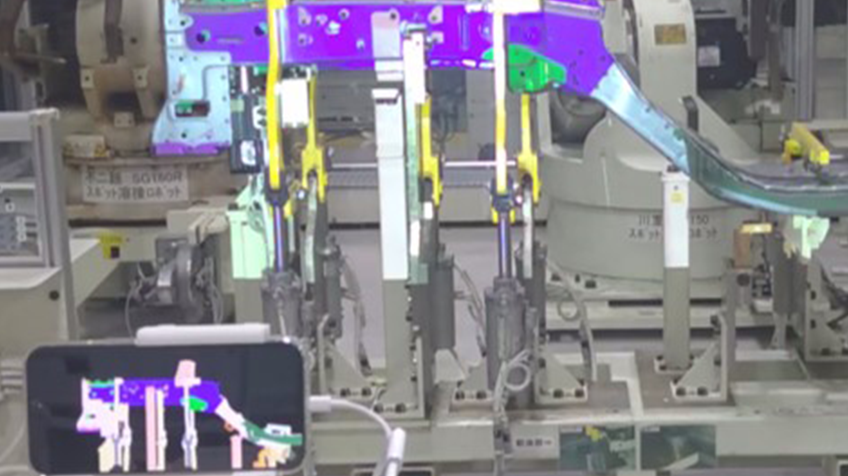

Projection mapping(Work order)

・Projection mapping on parts enables efficient operation.

・It is also possible to follow the projection onto a jig in operation.