Sustainability

Work style

What is the SDGs?

SDGs, which stands for “Sustainable Development Goals”, was adopted at the United Nations Summit in 2015 as a set of international development goals from 2016 to 2030. It consists of 17 goals such as “INDUSTRY, INNOVATION AND INFRASTRUCTURE” and “SUSTAINABLE CITIES AND COMMUNITIES” in pursuit of achieving a sustainable world.

Initiatives for work style

3 Good Health and Well-being

To ensure healthy lives and promote well-being for all at all ages

5 Gender Equality

Achieve gender equality and empower all women and girls

8 Decent Work and Economic Growth

Foster sustained, inclusive and sustainable economic growth, full and productive employment and decent work for all.

9 Industry, Innovation and Infrastructure

Build resilient infrastructure, promote sustainable industrialization and foster innovation.

10 Reducing Inequality

Reduce inequality within and among countries

12 Responsible Consumption and Production

Ensure sustainable consumption and production patterns.

TPEC’s Initiatives for the SDGs

TPEC's Healthy Management Declaration

- 3 Pillars: "Manufacturing," "Human Resource Development," and "Healthy Development"

- An endless challenge to the ideal form

- Bright and open working environment

- Overflowing health improvement mindset

- Daily routines with good rhythms (eating, exercising, and sleeping)

- Creating the smiles of our All stakeholders with mental and physical healthy people

Health Management Initiatives

Aiming to create a body that continues to work in good health, we are working to foster health awareness among each individual and to improve lifestyle habits.

We have been certified as a "Certified Health and Productivity Management Organization" by the Ministry of Economy, Trade and Industry since the beginning of 2017, and have renewed our certification every year since then.

Gender equality activities

Certified as Aichi Women's Advancement Promotion Leader

Having been appointed as a promotion leader to announce activities in Aichi Prefecture, we are implementing initiatives aimed at the active participation of diverse human resources, including women.

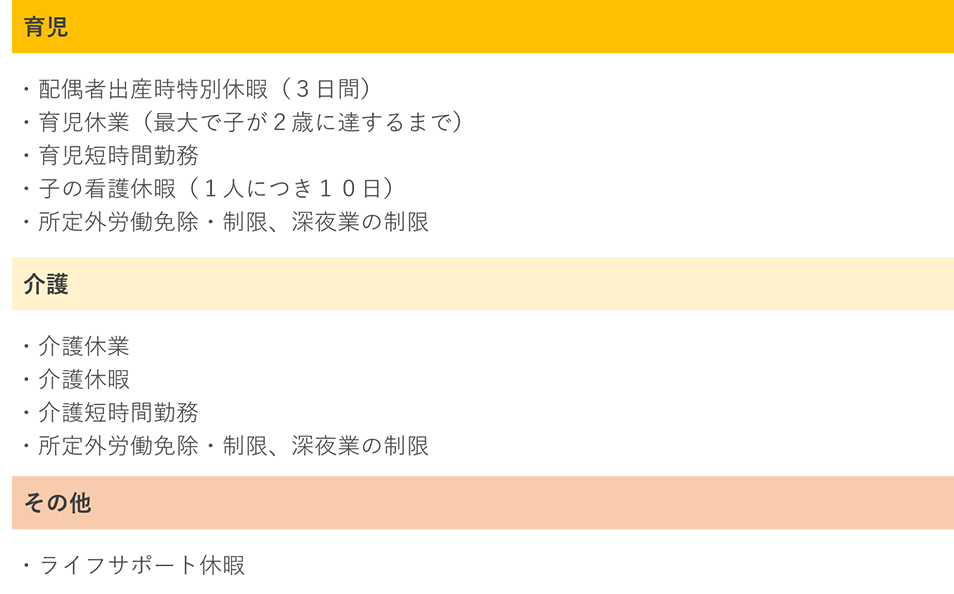

Balance Support System

At our company, we are working to create an environment where both men and women can play an active role, with the concept of working styles that suit each person's life stage, with the aim of creating a workplace where everyone can work comfortably and rewardingly.

Creating employee-friendly and decent workplace

We were awarded the grand prize of “ Workplaces where working people shine lively” by Toyota city.

Our company was highly evaluated as all the employees worked together for measures such as “reduction of the working hours for employees permitted by Special Provision of 36 Employee-Employer Agreement” and “Coreless Flexible Working Time,” as part of work style reforms we have promoted since 2017.

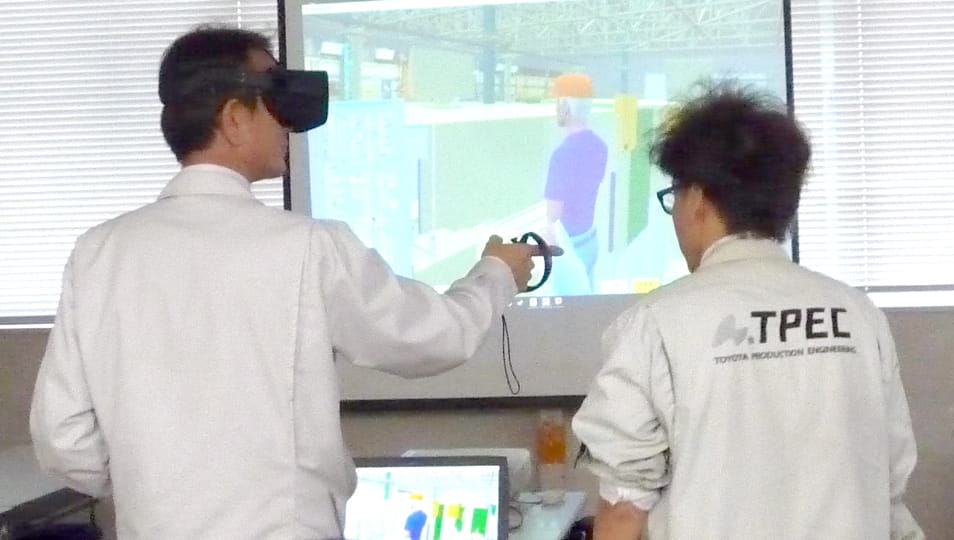

Study utilizing VR technology

We adopted VR technology in various fields.

Establishing a study method using VR enables a check of workability(including postures, flow lines and spaces) in full size which was only possible on paper before.

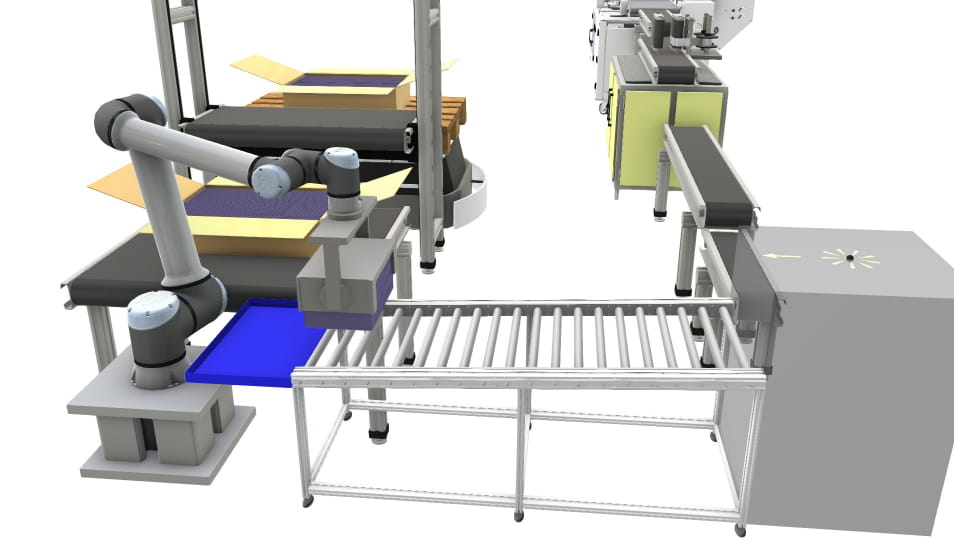

Expanding our services with capitalizing on our forte

Business with Toyota Motor Corporation led us to expand our services to new business areas in supporting companies outside of our group with robots.

We offers services of our specialty to other companies. In new business areas besides one with Toyota Motor Corporation, we adopted robot study, “Jidouka” study, etc., leading to personnel saving, quality improvement and environmental upgrading.

Contribution to Toyota Environment Challenge 2050 with digital study

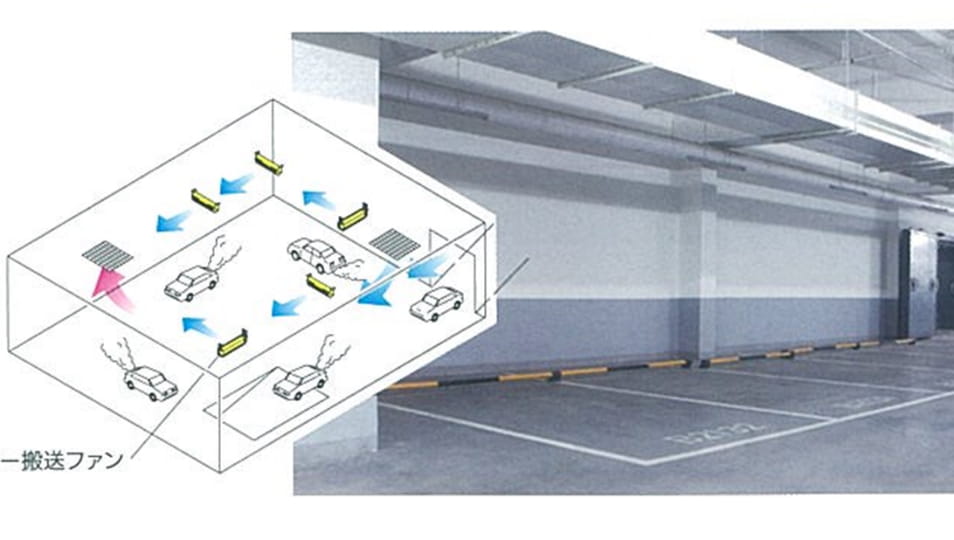

Initiatives for minimizing suction equipment for discharging gas at automobile inspection in preparation for Toyota Environment Challenge 2050

Equipment specification study with CAE analysis of airflow.

CAE caluculates conditions to create air flow over the entire automobile inspection line. Optimal conditions lead to large effects such as CO2 reduction, noise-reduction and cost saving.

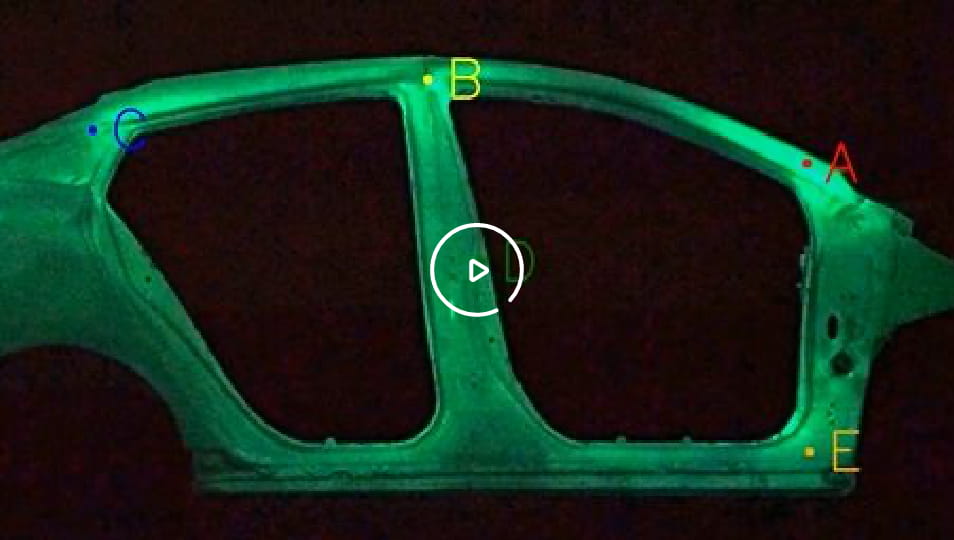

Practical application of Mechanoluminescent technology

Practical application of stress visualization using Mechanoluminescent technology enables visualization of ones of instrumental panels, resins, dies and jigs(strain visualization).

Practical application of stress visualization helps to figure out the trouble mechanism which had been unknown before, in addition visualization of stress distribution allows an optimal method proposal.

Usage of air flow visualization techniques

Air flow visualization techniques are used in various areas contributing to trouble shooting. The scope of their application has been expanding.

Visualizing air flow which could not be checked with eyes before helps to figure out trouble mechanisms. In addition, we got a great command of the video analysis method(PIV), resulting in the higher level of analysis.

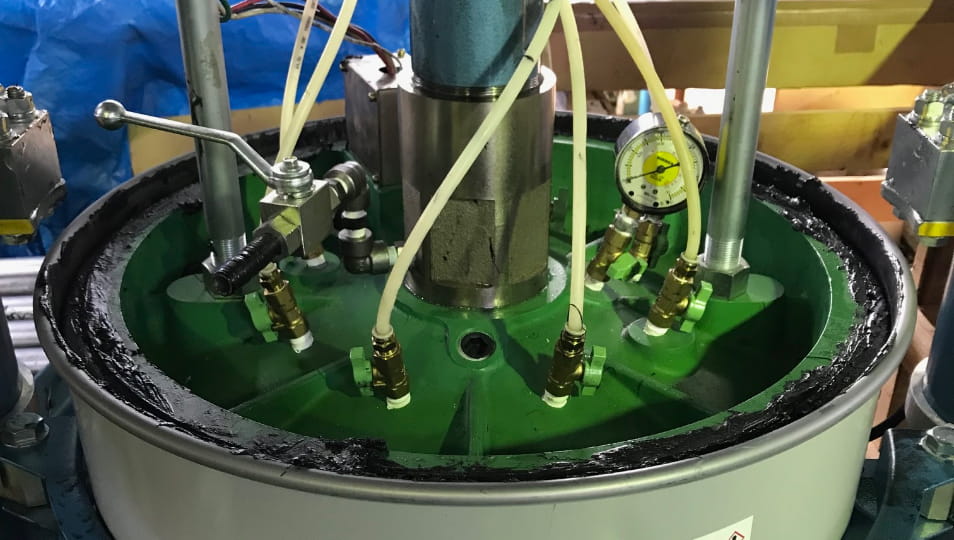

Building a factory IoT platform for fault symptom management

Building a factory IoT platform achieves the optimal preventive maintenance for equipment stop prevention

Introducing a fault symptom detection system of crankshaft grinders enables a fault symptom detection achieving visualization.

We contribute to the reduction of customers’ work hours including those for maintenance and for parts procurement.

Anomaly detection using machine learning

Development of automatic crack detection technology on pressed panels using AI prevents cracked panels outflow.

AI learns crack images to detect cracks automatically. Using AI enables 100% inspection so as to prevent an outflow of defective products to a post-process.

Promotion of diversity

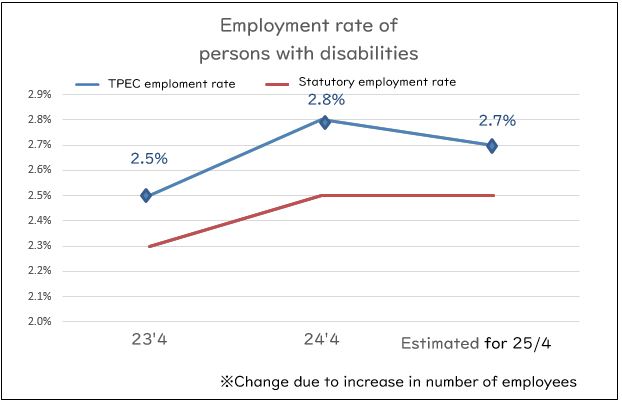

Initiatives to promote employment of people with mental and physical disabilities

- Improvement of working environment(expansion of work-at-home system)

- Expansion of special leave system (for acquisition and renewal of disability certificate ,treatment of a person with disability by physical difficulty, necessity of rehabilitation, etc.)

Contribution to Toyota Environment Challenge 2050 with digital study

IT support for ALL-TOYOTA reducing residual urethan activity as a Part of TOYOTA Environmental Challenge 2050

We studied the plate shape with CAE analysis to achieve using up urethane for reducing residual urethan to be disposed of, which led to the proposal of an optimal shape.