TPEC’s ROLE

Digital Engineering Field CAE Technology

Our Mission

Reproducing various current conditions with using CAE for problem prediction and countermeasure proposal

We use CAE to virtually reproduce various phenomena, such as material deformation in sheet metal press forming and the flow of molten material during the molding process of resins and castings. By predicting possible problems before fabricating molds and molding dies, we are able to make improvements, thereby reducing the number of rework after die fabrication, which in turn contributes to time and cost savings. The use of CAE to visualize any phenomenon leads to a correct perception of the phenomenon.

Our Direction

We will contribute to making ever-better cars with understanding physical phenomena and leveraging CAE technology.

- Shrinking the amount of time to develop a new vehicle

- Improvement of perfection at the drawing stage

We propose and create CAE technologies to be used and relied on not only for vehicle production but also for customers’ problems solution.

- Striving to be engineers carrying TPEC’s core technology

- Proposal of simulation technologies.

Our Capabilities

Supporting Monozukuri(manufacturing)

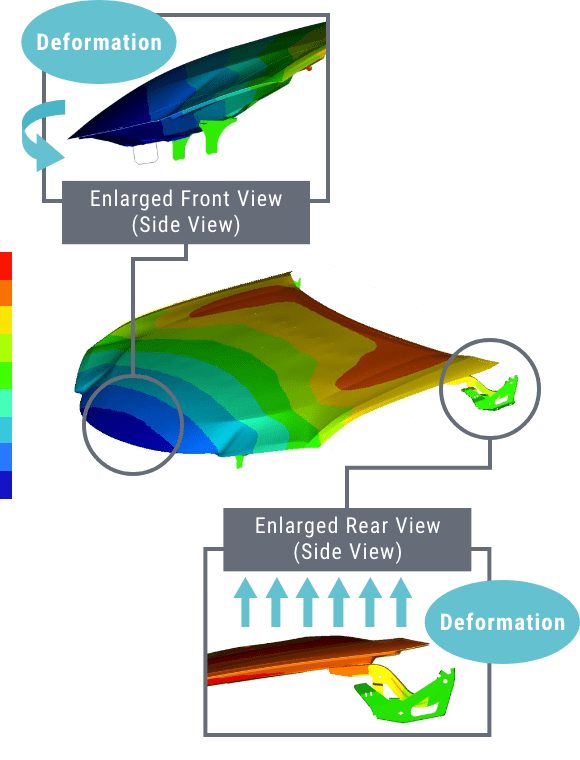

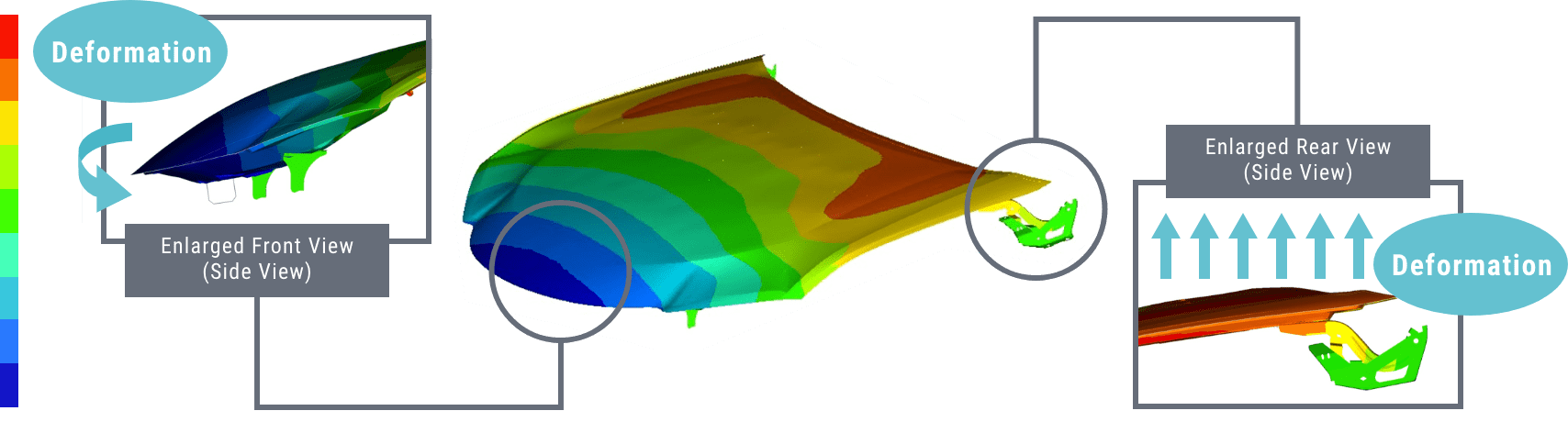

- Prior to produce a press mold of sheet metal, we study the formability with simulation, visualize and predict defects including cracks occurring in forming process to feed back to the design department.

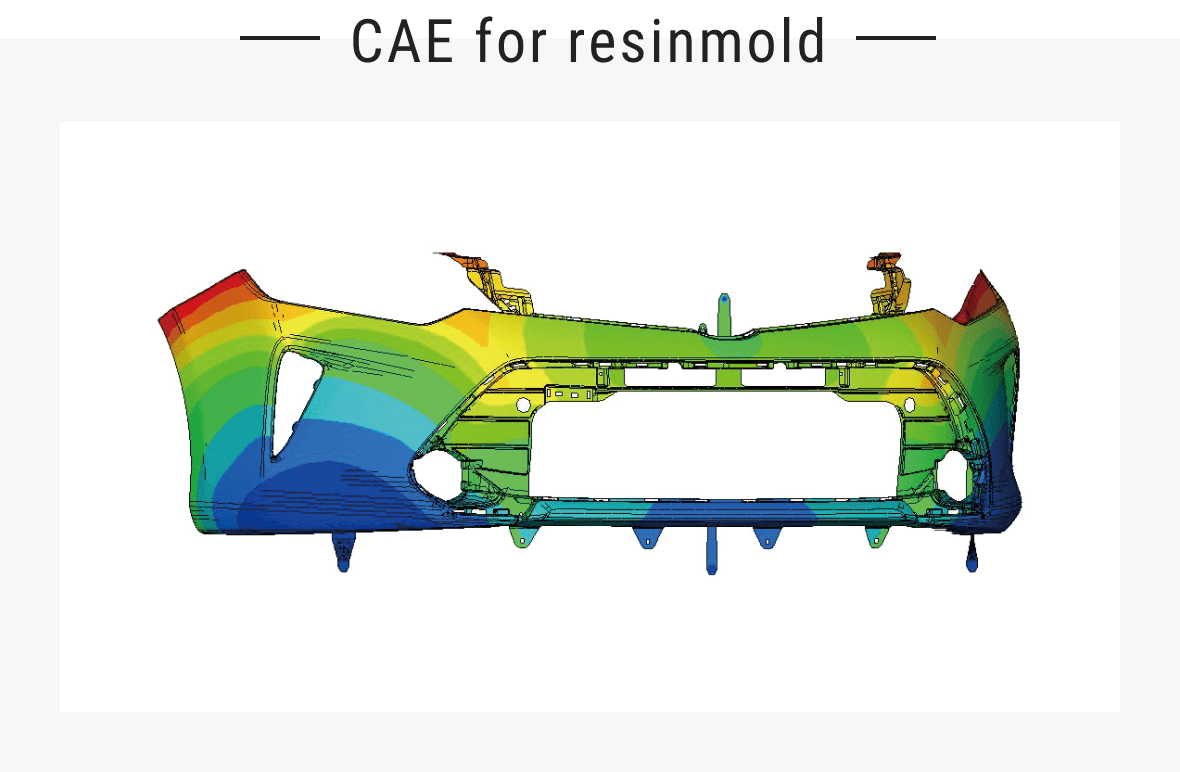

- We calculate the flow of resin during injection molding and changes in temperature and pressure to predict molding defects after molding is completed.

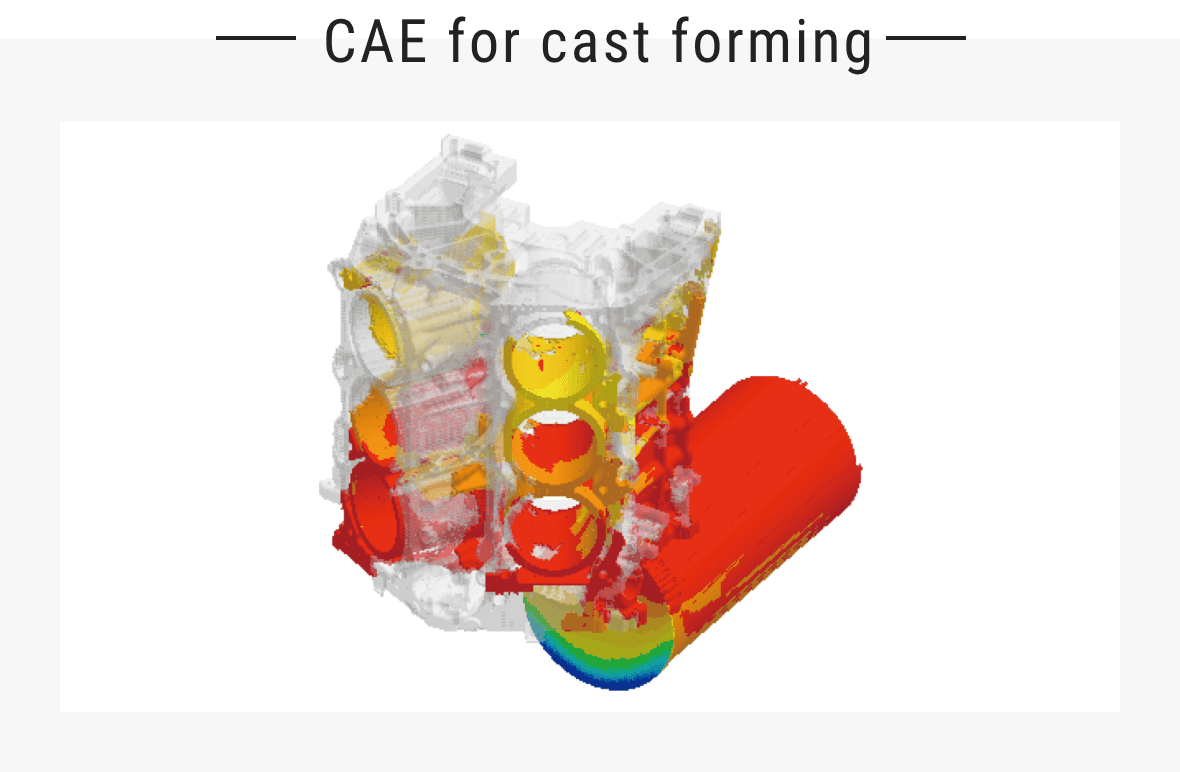

- We visualize a flow pattern of molten metal in a mold. We calculate the flow velocity, temperature and viscosity, etc. in the flow to predict a molten metal flow pattern of large scale and defects including air trap.

- We predict shapes with large deformations, plate thickness distribution of products, plastic strain due to deformation, etc.

Factory Study, Equipment Study Support

-

Equipment strength prediction technology We visualize robot movements considering inertial force,

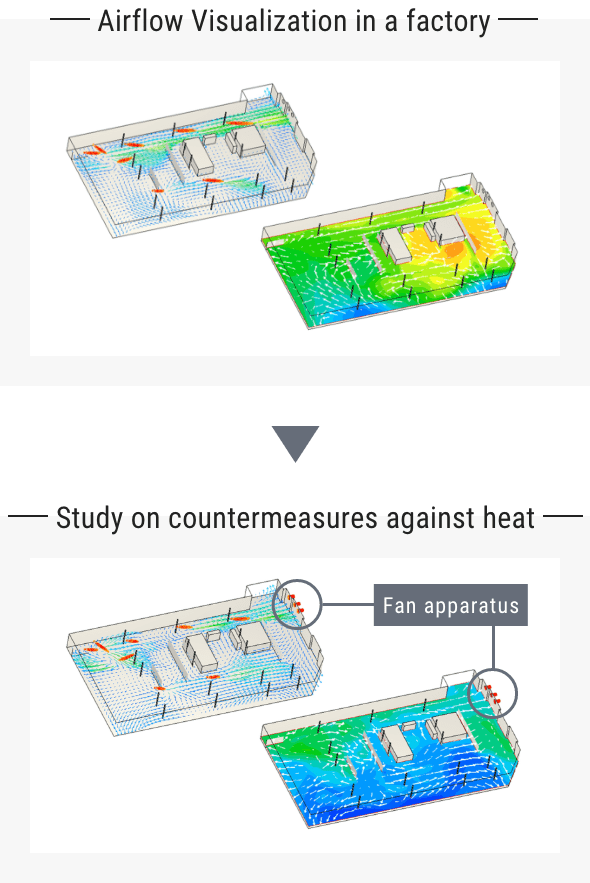

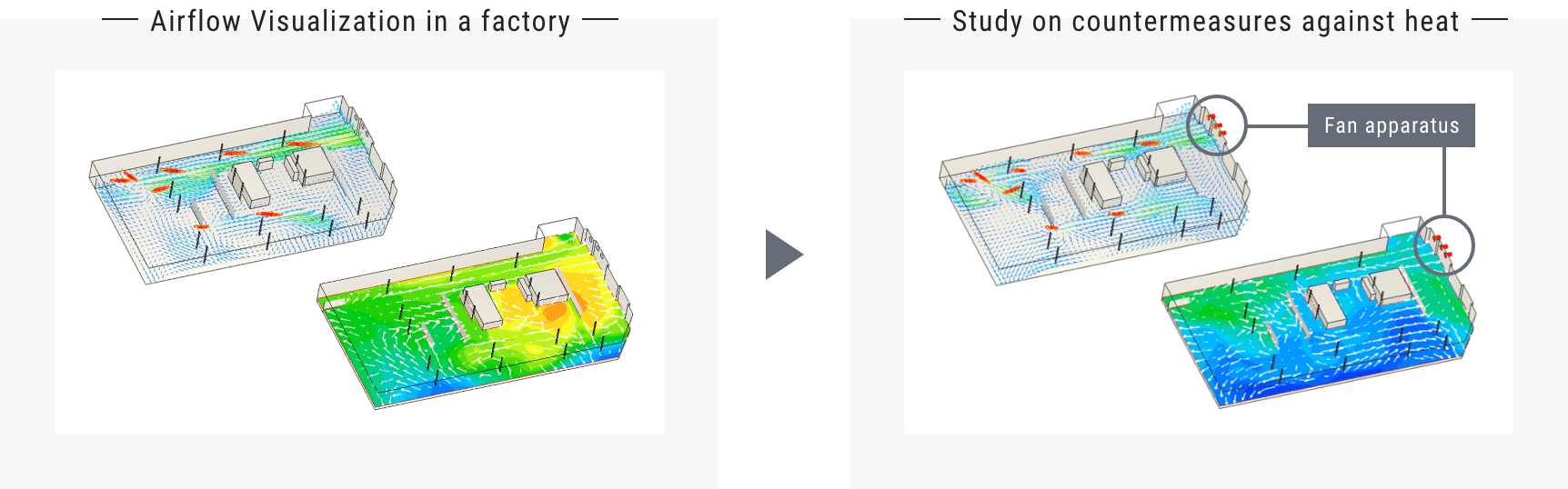

e.g.: prediction of material handling strength, frame strength, etc. by mechanism analysis introduced elastic body. - We reproduce the airflow in the factory with CAE, simulate the flow of unseen airflow gas, and help create an environment.

Vehicle Study Support

- We visualize deformation and position misalignment caused by parts such as weather strip to support countermeasures against deformation and likelihood studies.