TPEC’s ROLE

Actual Engineering Field Production Tryout Support

Our Mission

Studying factory lines virtually with using digital engineering to promptly start up them as actual ones

We utilize digital engineering to introduce manufacturing lines that take into account high productivity and safety, and to prepare for manufacturing in a planned and efficient manner. In addition, we will link the knowledge that can only be obtained from actual phenomena in the quality construction process to elemental technologies, leading to the establishment of more advanced manufacturing technologies and the construction of a database of more accurate digital studies.

Our Direction

We will contribute to high-qualified and high-efficiency car production at low cost with determining trouble-free facilities and processing conditions through full use of digital engineering.

- Establishing process facilities and processing conditions considering quality, cost, workability and safety

- Reduction of redo with actual equipments with verifying the level of process completion and processing conditions feasibility

Our Capabilities

Virtual Presence

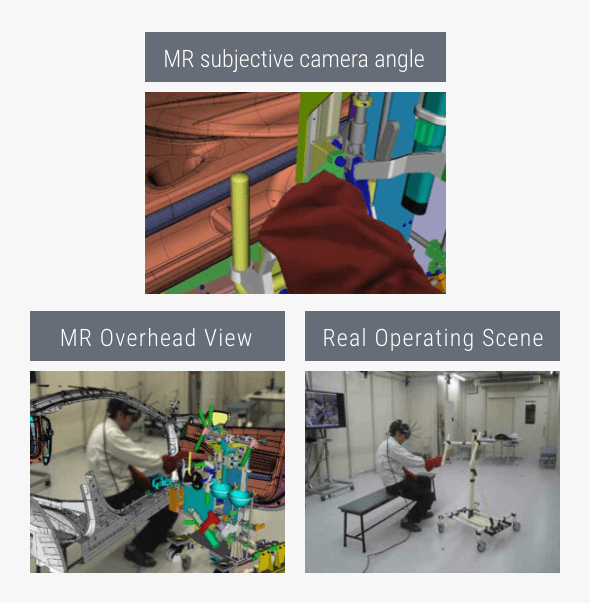

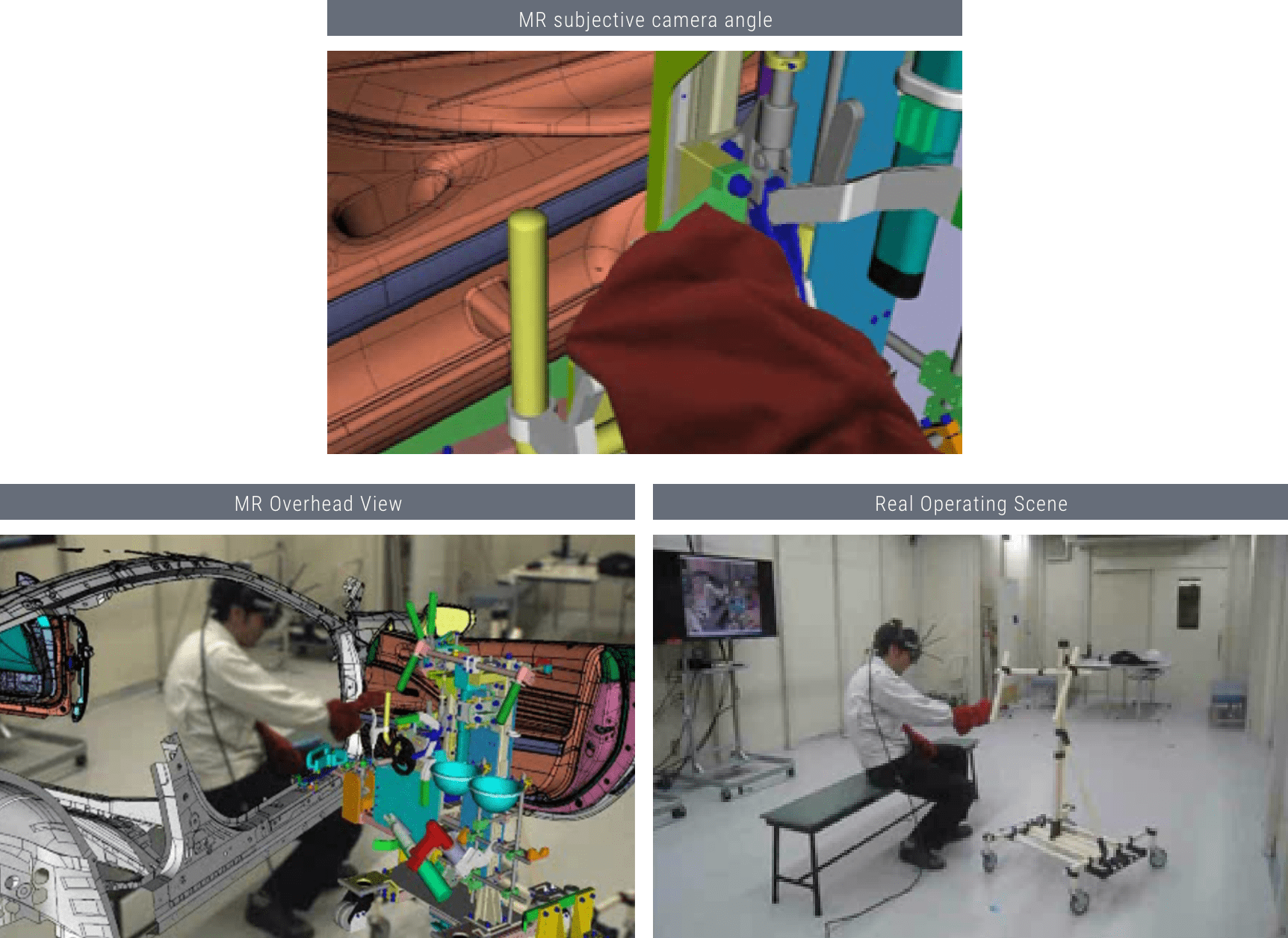

The study of workability of door attachment equipment with the use of MR technology(shows below)

With 3D data of equipment in conjunction with a simple equipment made of elector pipes we reproduce a sense of actual operation in order to check usability, detect interferences with attached facilities and identify problems. Using MR enable us to identify more problems than ever before.

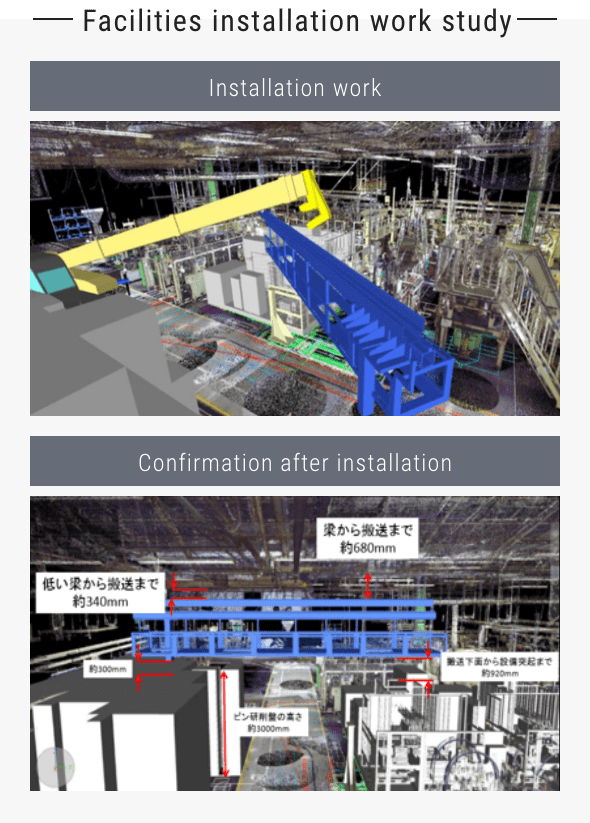

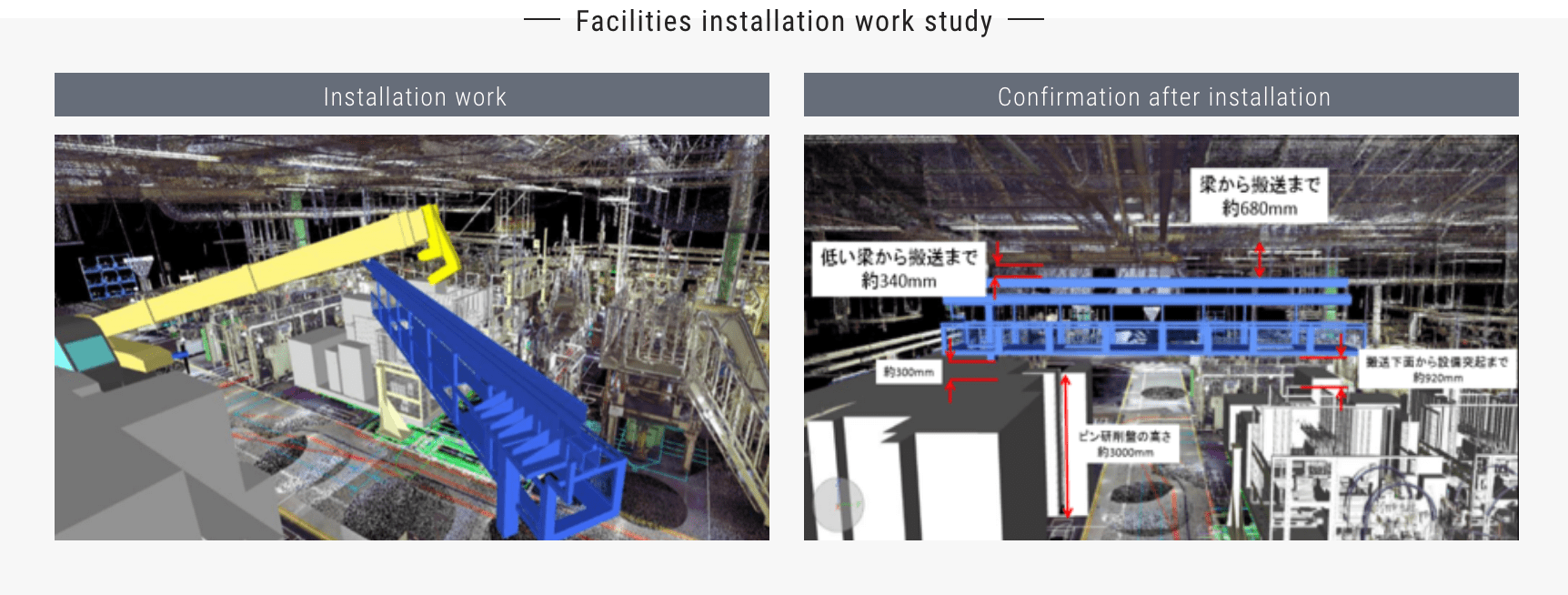

3D Construction Plan

We reproduce carrying in/out work with using data to check the working space or interference in advance, then verify the safe operation plan and procedure prior to leaving for the actual place.

Process Maintenance and Quality Requirements Establishment

After the equipment installation on-site, we adjust facility conditions for mass production. We accumulate the processing point measurement data, the accuracy of processed products and quality data.