DIGITAL T-time

DIGITAL T-time

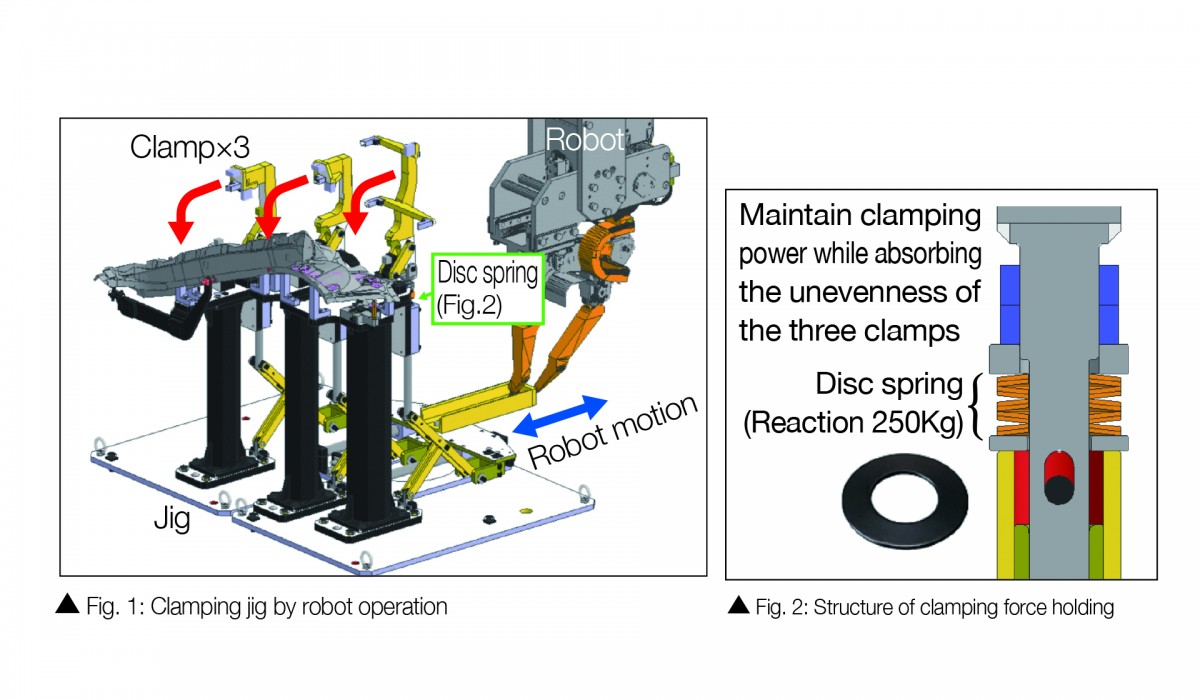

Efforts to reduce CO2 by eliminating clamping power

●Energy-saving and CO₂ reduction activities through our core businesses (Design and manufacture of clamping jig utilizing karakuri linkage and disc spring)

Although there are jigs that use compressed air to fix components, many CO2 are required to create compressed air. Therefore, we made an effort to develop an energy-saving design that can be fixed without using this compressed air. The point of attention is to use the waiting time of the existing robot instead of compressed air to clamp multiple places in one operation (Fig. 1) and to adopt the reaction force of the disc spring to hold the clamp (Fig. 2). We have succeeded in designing a system that can reduce CO2 (about 70% of electric power) repeatedly through trial and error. We plan to reduce the operating force and reduce the weight of the jig for practical use in the future (patent pending).