DIGITAL T-time

DIGITAL T-time

Initiatives in our main business operations

●Efforts to reduce water and electricity of completed vehicle water leakage inspection equipment

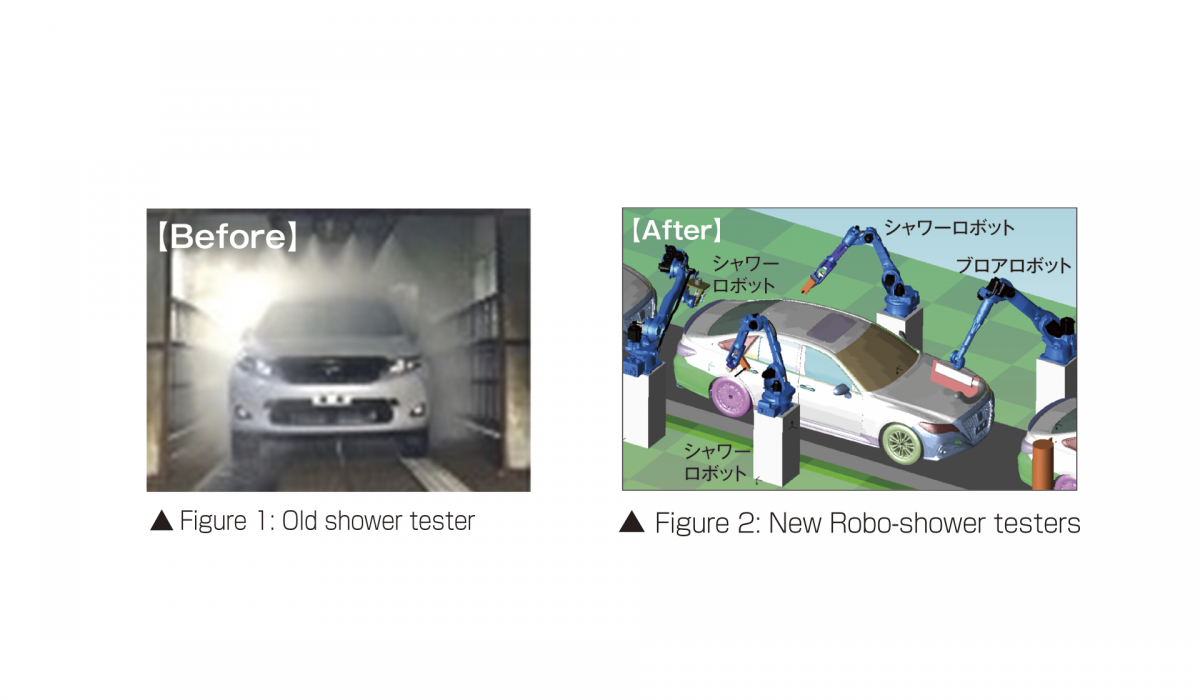

In the vehicle inspection process, water leaks are inspected (water is splashed with a shower and then blown off with a blower to check that there is no water leak or entry in the vehicle interior, etc.). Since large amounts of water and large air flow fans = large amounts of electricity used (Fig. 1), we worked to develop and introduce a new shower tester (Fig. 2) that uses robots to achieve the goal of zero-industrial CO2. How to reduce the amount of water and electric power while improving the water leakage detection power and blower performance? Focus should be to water only the areas required for the inspection, and reduce fan capacity by approaching the distance between blower nozzle and the vehicle. Using robot teaching and CAE analysis (air flow visualization), which are TPEC's specialty, optimization studies of robots were carried out. As a result, we succeeded in reducing water consumption by 52% and electric power by 17%! We introduced this system to Toyota's Motomachi Plant and China Plants, which produce environmentally conscious BEVs (electric vehicles).