DIGITAL T-time

DIGITAL T-time

Initiatives in our main business

●CO2 reduction by measures for bumper injection molding silver streak defects

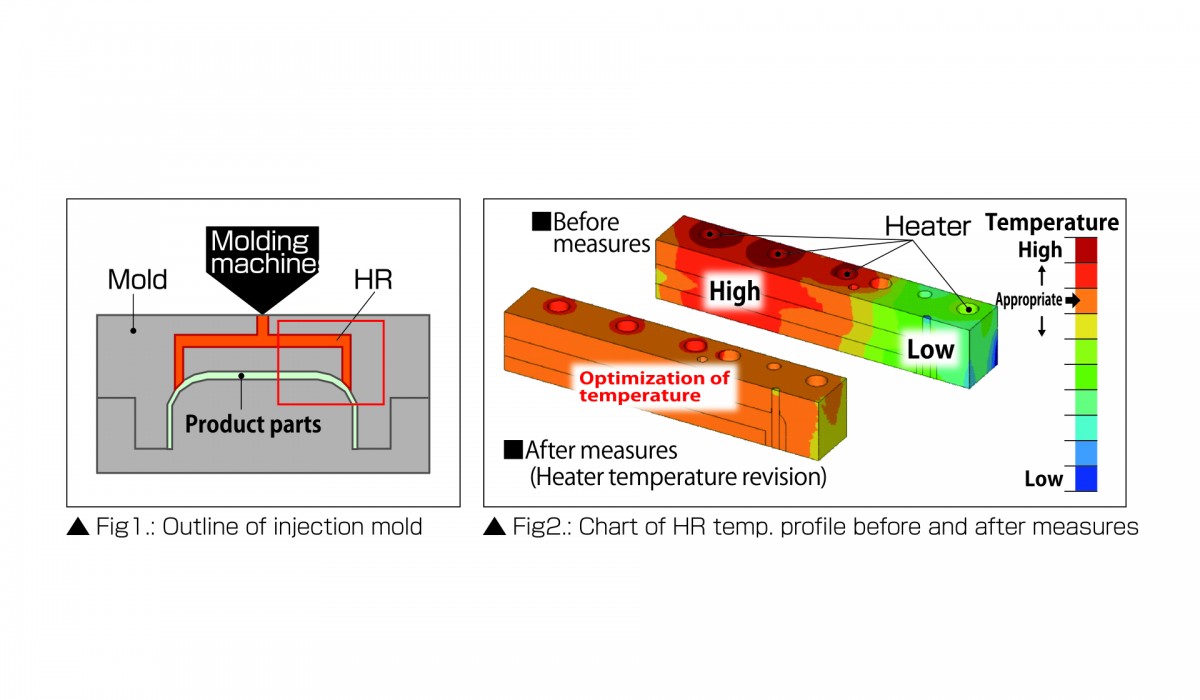

In the molding of resin parts such as high-design bumpers, a mechanism for raising the temperature of the resin by a flow path called a hot runner (hereinafter referred to as HR) is adopted in the mold, (Fig1.)but after the end of the workday, the cold resin remains, leading to the occurrence of silver streak*1 defects due to uneven temperature rise at the beginning of work.

This time, CAE is used to visualize how cold resin warms up in HR (Fig2.). Calculate the setting conditions for each heater so that the remaining resin can be efficiently heated to an appropriate temperature. As a result, the number of defects in the silver streak was reduced to zero, and this led to a reduction of 0.135 kg of CO₂ emissions per bumper. We will continue to contribute to the realization of carbon neutrality by utilizing the "CAE" in response to various problems.

※1:Defects in which the gas or air in the resin appears as a whitening streak-like marks on the product's surface