DIGITAL T-time

DIGITAL T-time

Initiatives in our main business

●Paperless system through electronic vehicle inspection methods

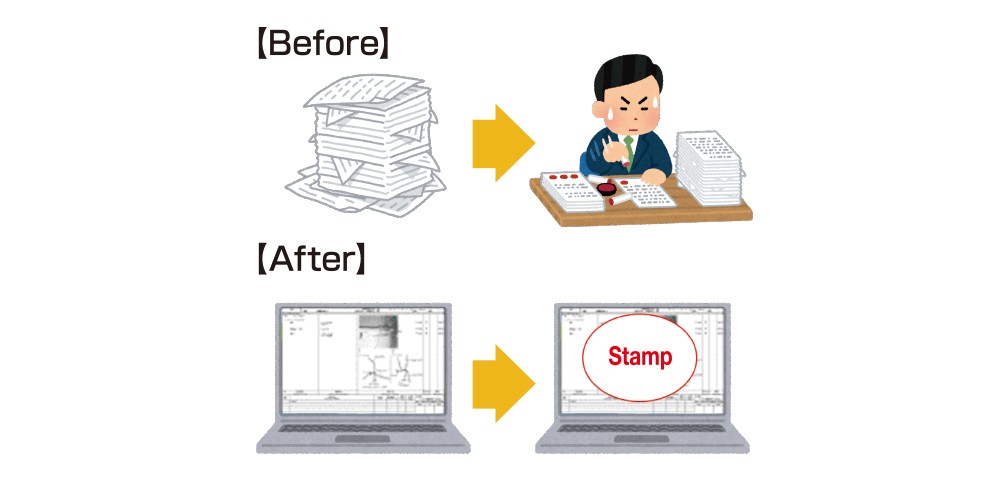

▲Image of approval flow

In the inspection process for completed vehicles, approximately 3000 items were inspected, and TMC's Motomachi Plant Vehicle Quality Div. entrusted TPEC with the operation and management of a vehicle inspection method system that compiles a database of inspection items. Forms for inspection content created by the system are printed on paper, approved by supervisors, and managed on paper, requiring a large amount of paper. (Approximately 18000 sheet /PJT)In addition, it takes a lot of man-hours to get the approval and stamp of the supervisor for each inspection. This time, in cooperation with TMC, we have begun computerization of forms and electronic approval of the system with the aim of streamlining the paperless and approval work. Respond to requests for functions and operations from each factory, and promote specification creation, function development, and operation support. As a result, we have succeeded in reducing about 380,000 sheets of paper and about 2,000 man-hours per year in TMC! To further expand the benefits, we are expanding the system horizontally throughout the Toyota Group, including overseas affiliates.