DIGITAL T-time

DIGITAL T-time

Business Report for the 32nd Fiscal Period (April 2022 to March 2023)

●New executive system

We would like to take this opportunity to express our deep appreciation to Toyota Motor Corporation and all of related business partners for their continued guidance and support. The new executive structure was approved at the June 26 Ordinary General Meeting of Shareholders.

President and Representative Director:Akitomo Baba

Managing Director:Kazuo Nishidate

Director (External):Shinya Eto※Toyota Motor Kyushu, Inc., MIYATA Plant General Manager, Vehicle Manufacturing Group

Auditor*Newly appointed:Keijiro Okabe※Change of Title from Director

Auditor (External):Yoshio Nakamura※Toyota Motor Corporation, Deputy Chief Officer, Production Group

●32nd Fiscal Period (April 2022 to March 2023) Business Report (Excerpts)

▼ Safety, Health/Compliance: Promote company-wide activities to raise employee awareness and foster a corporate culture

▼ Solidify the foundation: Improve "job satisfaction" and "motivation" by reviewing personnel system and training

▼ Strengthen corporate structure (strengthen competitiveness and independence): Promote the expansion of the scope of application of technologies utilized in existing operations Proposals, technological development, and expansion into growth fields that lead to improved productivity at manufacturing sites

▼ Sustainable Growth: Promote proposal-based activities to build and expand the use of digital platforms

●Consolidation of foundation

▼Promoting Diversity

Toward the Elimination of the Gap in Education

Our goal is to provide rewards for people of all ages and educational backgrounds, and we are making step-by-step corrections toward the complete elimination of this program in fiscal 24.

▼Strengthen human resource development

Revision of Role and Competence Requirements by Qualification

Based on the TPEC-WAY, we have revised the "TPEC Human Assets" to emphasize the two requirements of "Thinking Ability" and "Human Power". We will promote the growth of human resources (assets) who can flexibly respond to changes in the environment and think and act (challenge) on their own toward reform.

Baba Seminar, a special training program for executives

We are working to raise awareness and reform our behavior as a leader of the company through friendly rivalry between executives.

●Upgrading corporate management capabilities

▼Improving the added value of manufacturing

Reducing Production Preparation Lead Times

We are promoting proposals and technological development that will lead to improved productivity at manufacturing sites. For example, we reduced the analysis lead time in the painting CAE by half, so that it can be used for off-line teaching studies, which contributes to reducing the frequency of film thickness adjustments on-site.

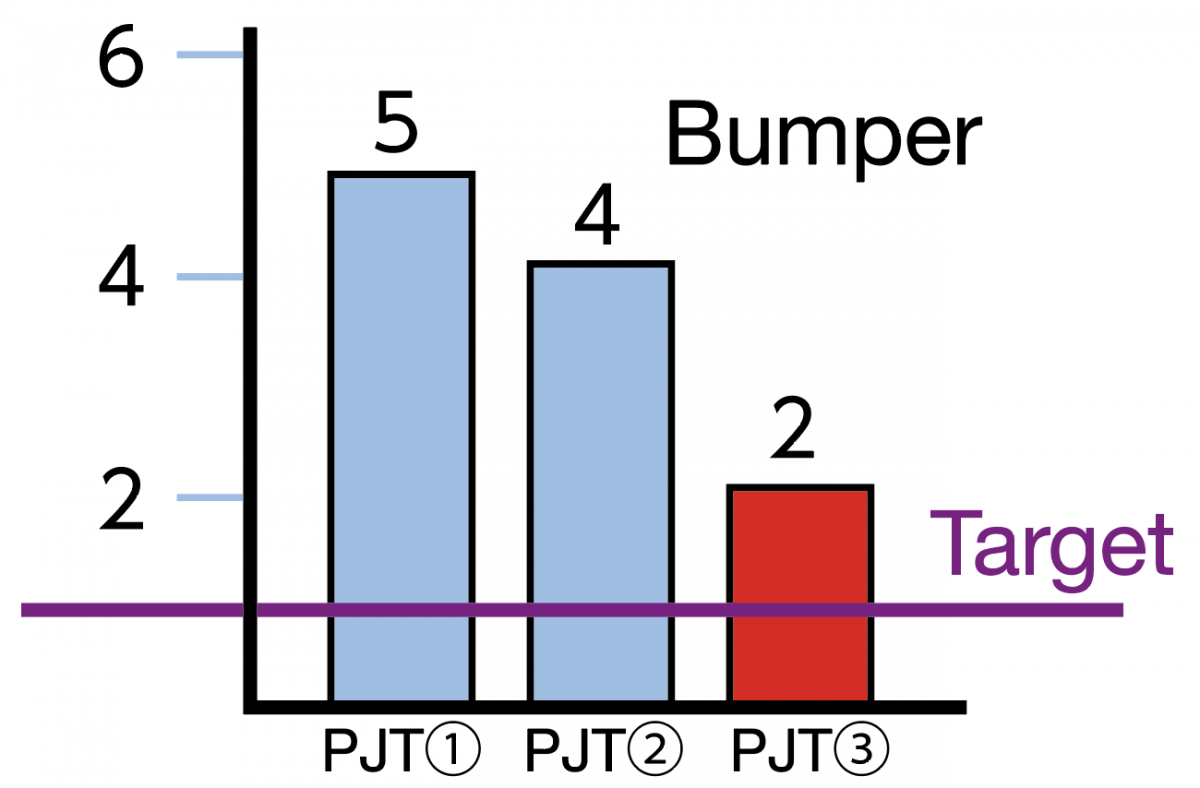

■Number of times of paint film thickness adjustment in actual machine

[Forecast of Coating Film Thickness: CAE]

・Improving first-time quality by reflecting CAE findings

・Decrease in number of adjustments (5→2times)

▼Taking on the Challenge of Expanding Business Domains

Promotion of DX in the area of batteries

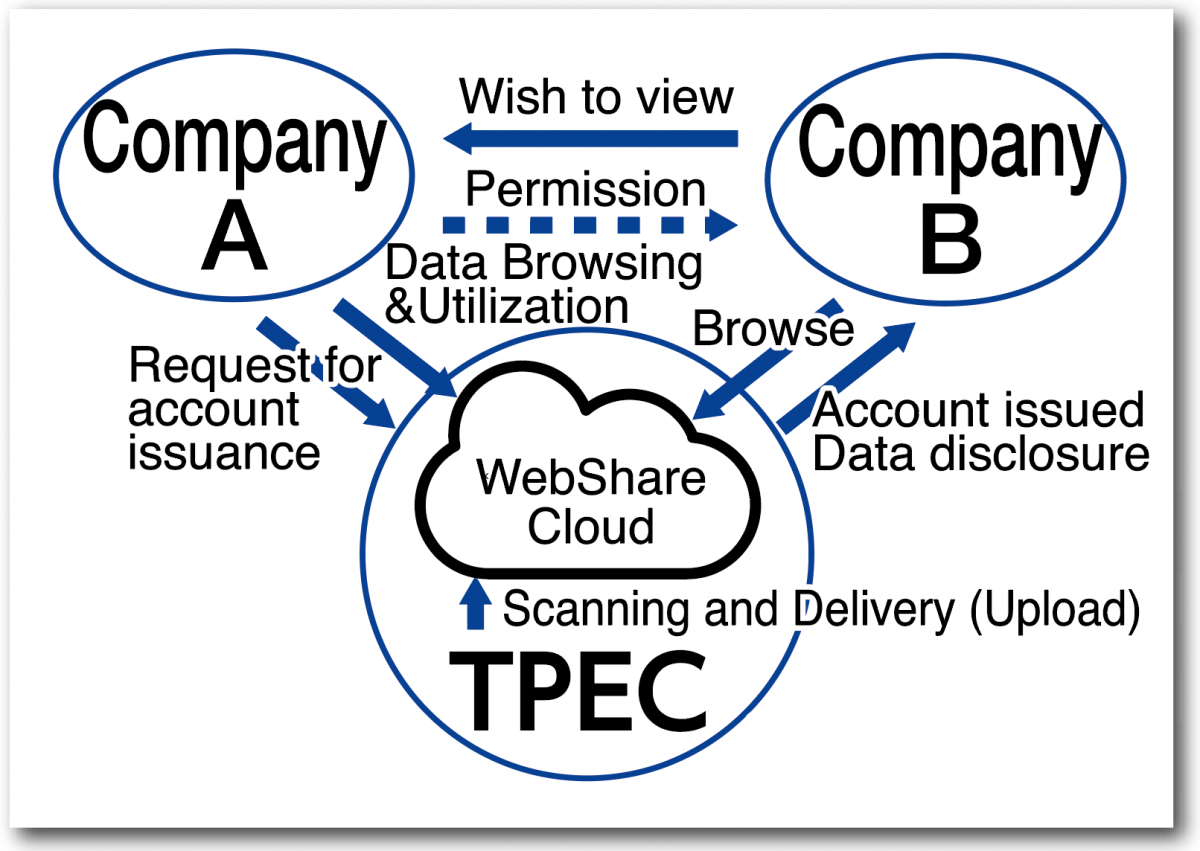

Build an environment that enables access from multiple sites by centralizing point group (shape) data of factories and lines through cloud. We are promoting the sharing of data among affiliated companies and the effective use of master line data.

▲Environment in which companies share information

●Sustainable growth

▼T-PEQ's construction

Toyota’s bill of Process, Equipment, Quality based System

Building a cloud-based platform

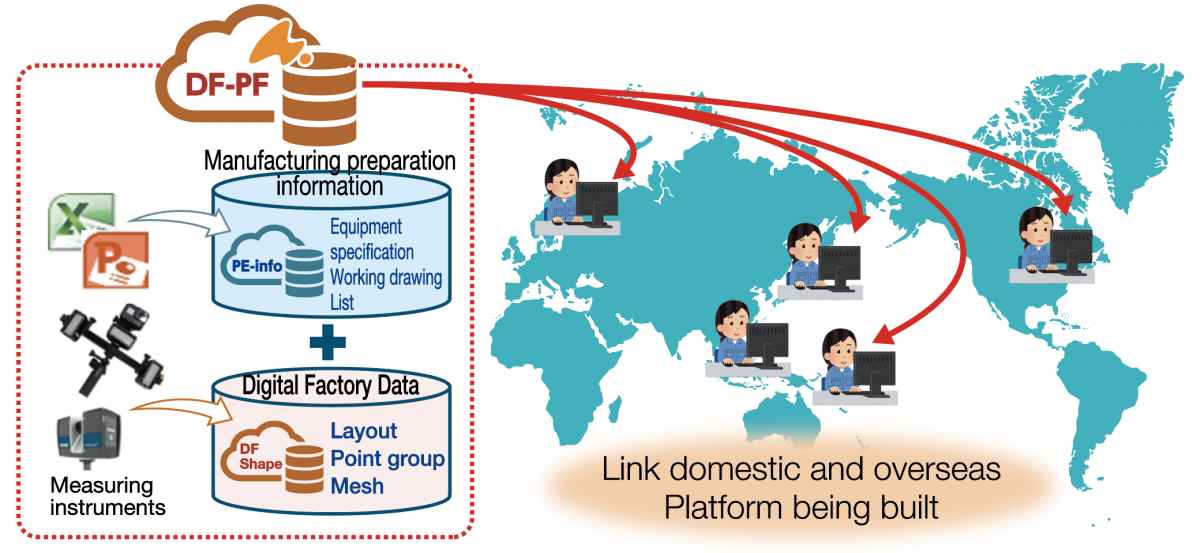

Constructing a facility data base in DF-PF (*) as part of T-PEQ's construction. We have begun to use it for configuration decision and robot studies.

*DF-PF®:Digital Factory Platform:Link domestic and overseas Platform being built

Efforts to Build a Comfortable DF-PF

The development of measurement techniques and processing functions has enabled us to shorten lead times to convert data and to share information in a timely manner.

▲To reduce weight, color, and L/T

Promoting the Utilization of DF-PF

We have begun using this system as a support tool for business management and human resource development, and are proposing the introduction of factory street views for in-line examination. We are taking on the challenge of further innovation in the manufacturing process.