DIGITAL T-time

DIGITAL T-time

Initiatives through Our Core Business

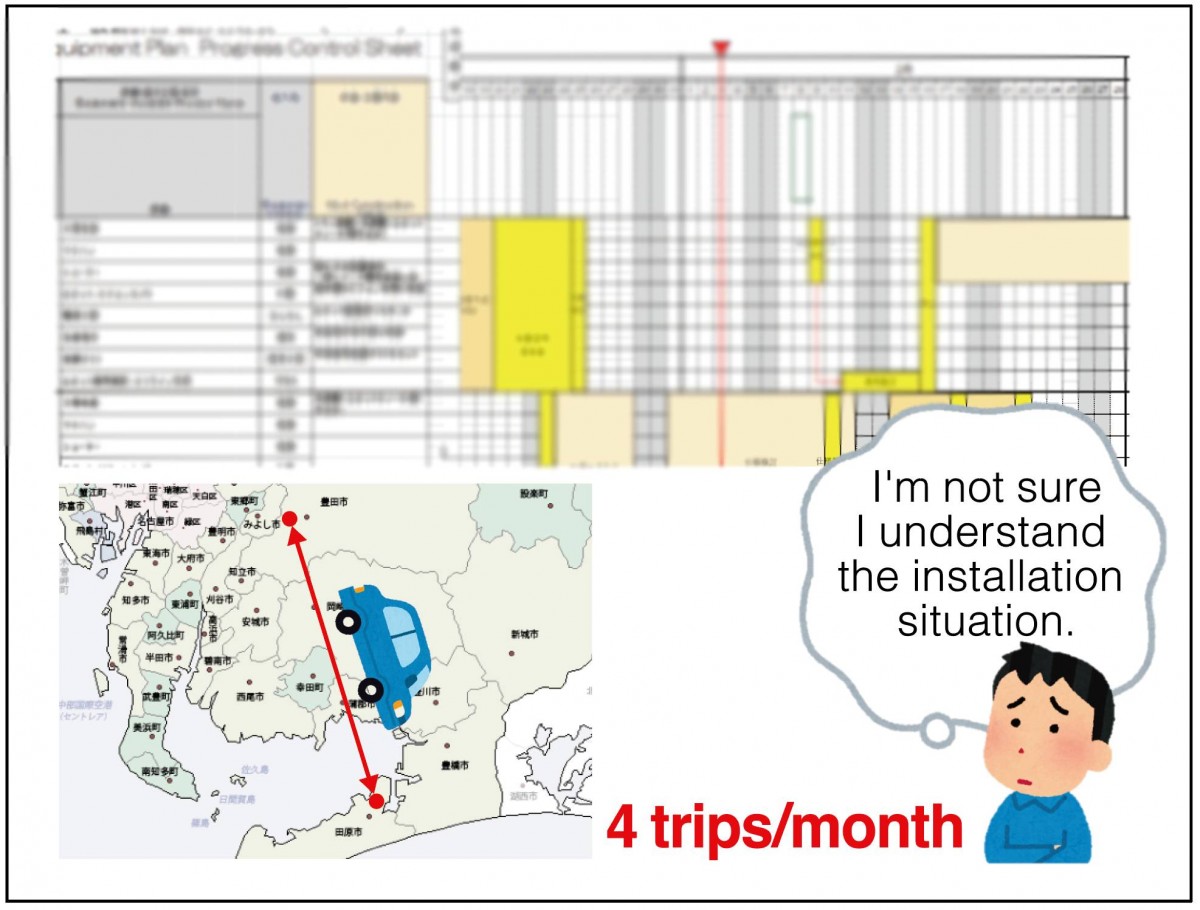

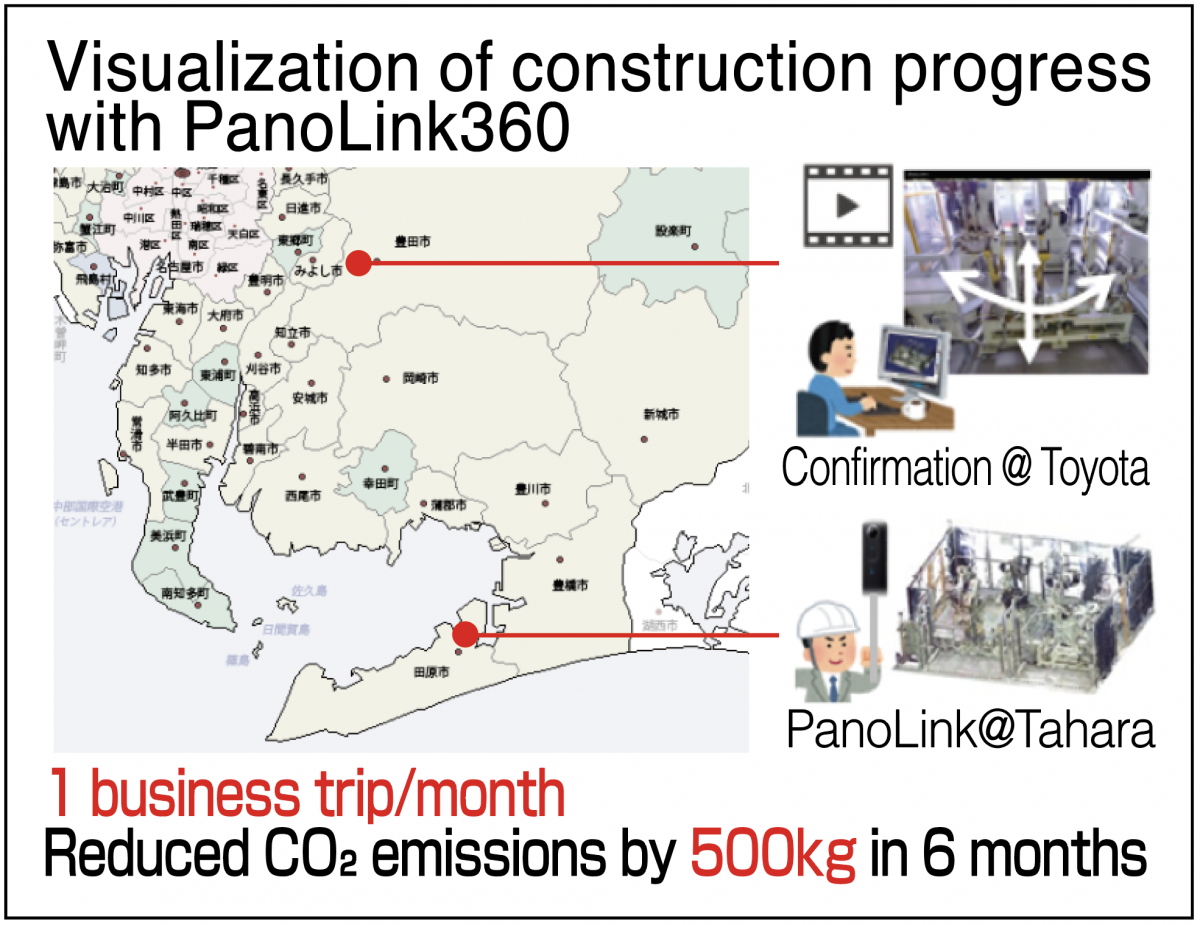

●Reduce business travel by using Panolink

Our group is responsible for installing a new body-welding process at TMC Tahara Plant, and has been installing and adjusting robots and facilities for approximately half a year. Progress management was carried out in the Excel schedule to check the daily changes in the situation, but the manager regularly traveled from Toyota City to check the situation because the actual situation was not visible. By using PanoLink360 to regularly shoot and check the status of the line from a remote location, we were able to reduce the number of business trips three times per month and reduce CO2 emissions by 500kg in six months, while promoting a work style that is not constrained by the location. We will contribute to further reducing CO2 emissions and reforming working styles while planning horizontal expansion to other operations.

▲Four award-winning ideas