DIGITAL T-time

DIGITAL T-time

Initiatives in our main business

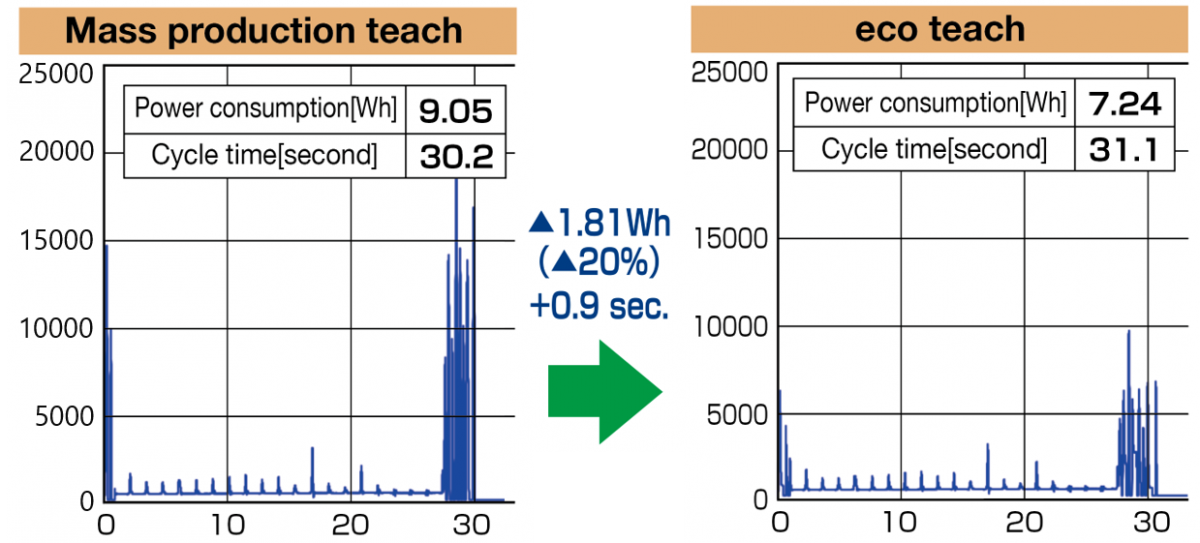

●Invention of Eco-Teach

TPEC has shipped approximately 3000 offline teach robots worldwide annually, mainly in the welding process. We verified this teaching data using a simulator and an actual machine, and devised a teaching method that can reduce power consumption by about 20% while maintaining production capacity. At the same time, motors and reduction gears also have a longer life and can reduce waste. Application of this eco-teaching to all robots is expected to reduce 90t/ annual CO₂ per line. We will contribute to CN by supporting the Teach-Eco system of our title robots and increasing the added value of offline teach shipped from TPEC in the future.

▲SPOT robot

▲Waveform of electric power(used by Kawasaki Heavy Industries development tool)