DIGITAL T-time

DIGITAL T-time

33rd Business Report (April 2023-March 2024)

●New executive system

We would like to express our deepest gratitude to Toyota Motor Corporation and all related parties for their continued guidance and support. A new executive structure was approved at the Ordinary General Meeting of Shareholders on June 21.

President and Representative Director

Akitomo Baba

Director

Kazuo Nishidate

Director(External)

Shinya Eto

Toyota Motor Kyushu, Inc. Chief Officer, Vehicle Manufacturing Group

Auditor

Keijiro Okabe

Auditor (External)

Yoshio Nakamura

Toyota Motor Corporation, Deputy Chief Officer, Production Group

▲(from the left-hand side) Mr Okabe, Mr Nishidate, Mr Baba, Mr Eto, Mr Nakamura

● 33rd Business Report (Apr. 2023-Mar. 2024), partial excerpt

▼Safety, Health and Compliance

・Promote company-wide activities to raise awareness and foster a corporate culture. Continue activities in the future.

▼Solid foundation

・Promote system revisions with diversity and flexibility in working styles that can respond to changes in the environment.

・Promote further improvements in productivity and added value and fair pricing activities by reforming business processes (DX).

▼Toward Strengthening Corporate Structure and Sustainable Growth

・Aiming for selection and concentration in growth fields, however, the response to unplanned needs and automation of conventional operations are less advanced than forecast, and the resource shift is in the middle of the way.

・Scenarios for expanding businesses and areas were slightly delayed, but progress was made as planned. Strengthen business in North America and build a digital engineering support system for Global South,

DE-PF(*1) Promote development and expansion of application,C4 (*2), etc.

●Consolidation of foundation

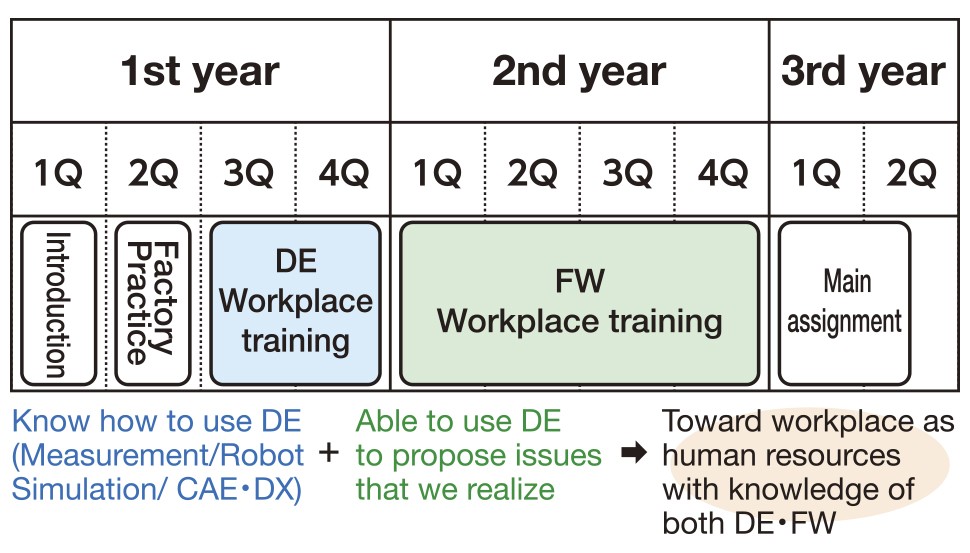

▼Strengthen human resource development

Strengthen training programs for new employees

We have reviewed the program with the aim of "fostering engineers who are familiar with both digital and field."Each workplace training is conducted prior to assignment, and the skills are acquired. This will lead to the early development of competitive power after assignment and the raising and strengthening of the technical capabilities of the company as a whole.

▼Promoting Diversity

Promote the creation of companies that "want to continue working"

【Creating a workplace where diverse workers can play an active role】

・System:Revision of Childcare/Family Care Leave Introduction of a system that can be acquired on a minute basis

・Awareness-raising:Lecture on International Women's Day (Advisor: Ms. Nagata, General Manager of Safety & Health Promotion Div of Toyota Motor Corporation)

・Culture:Received "Best Focus Award" from Toyota City for "Workers Shine Brilliantly Award"

▲Award ceremony for "Workers Shine Brilliantly Award"

●Strengthening of the corporate structure

▼Strengthen competitiveness

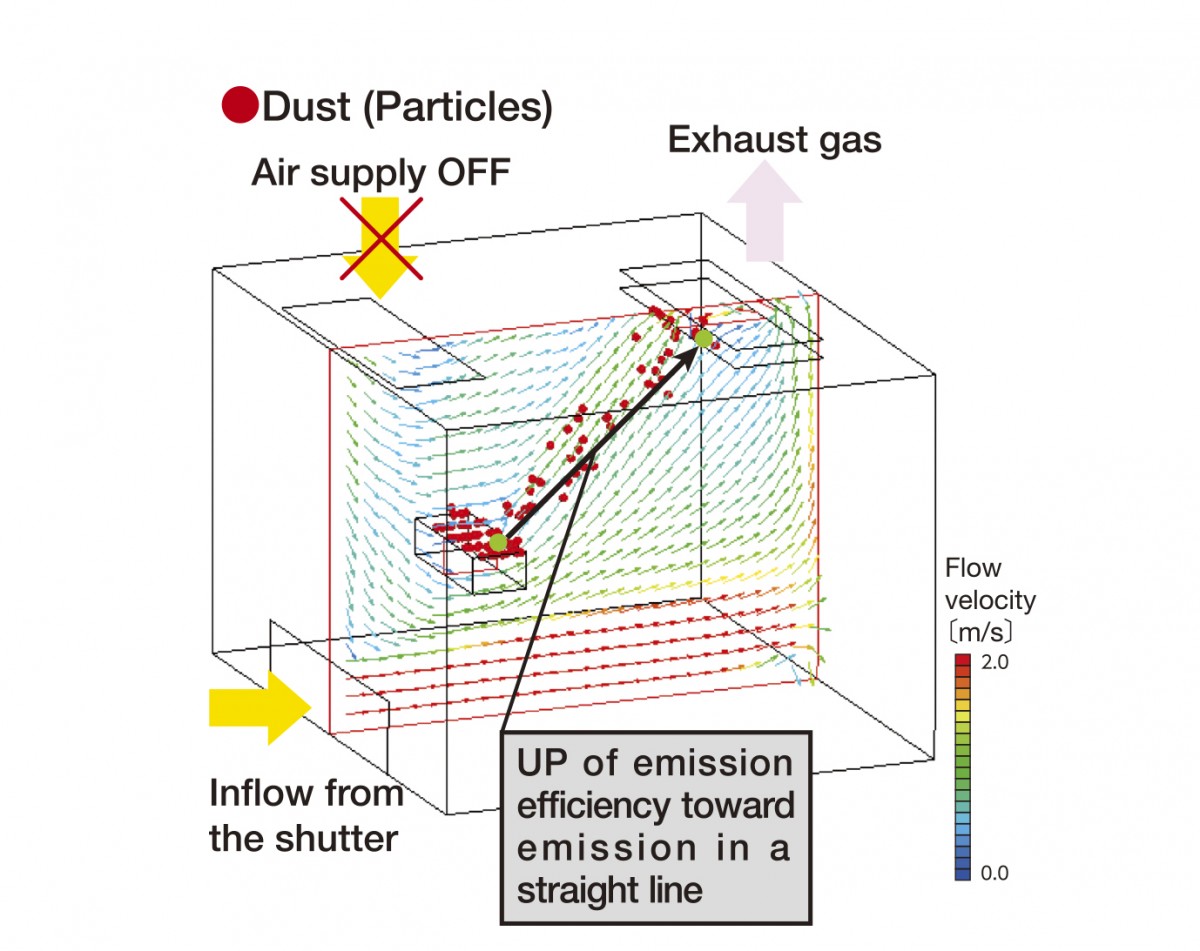

Evolve on-site-based DE and increase added value

We are beginning to see the effects of visualization technologies that we have been developing in advance.

【Air flow visualization】

The challenge is to solve the problem that welding fumes in the factory are not easily exhausted. We grasped the overall flow from the distribution of air flow velocity and temperature, and proposed the optimal direction of installation of the fan, number, and flow rate. It is also effective for countermeasures against high temperatures in summer.

▲Easy to understand the flow of dusts by flowing particulate markers

▼Expanding Business Domains

Creation of a ONE TEAM system

【Toward Strengthening Overseas Operations】

Currently conducting surveys and strategic planning in North America, China, Europe, Global South, and other region

【Large Room Activities】

Activities are being promoted to strengthen alliances with related companies, such as examining work methods, roles, and responsibility classifications.

●Sustainable growth

▼Building next-generation processes

Toward the Realization of T-PEQ's

-Toyota’s bill of Process・ Equipment・Quality based System-

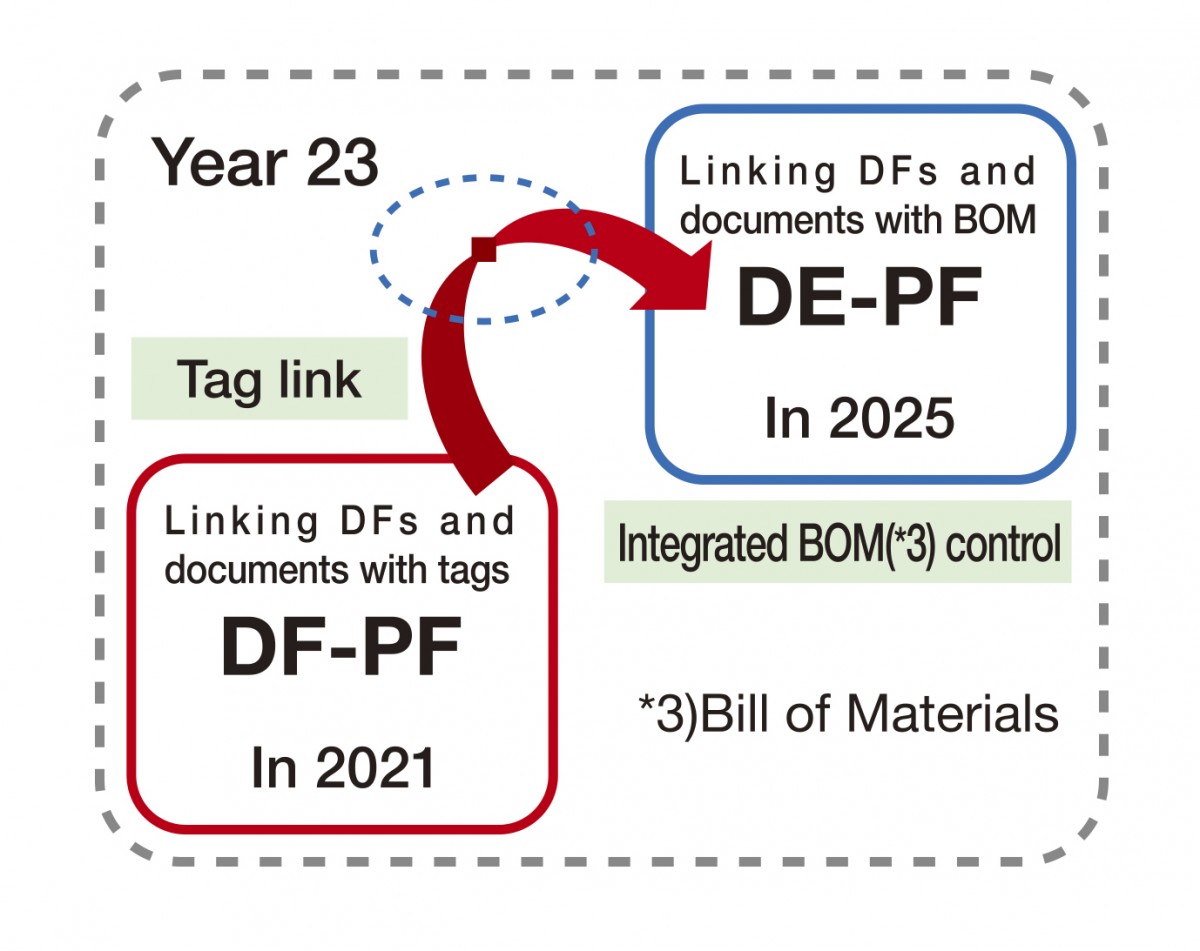

In the current fiscal year, we mainly stepped up from DF-PF (*1) utilization to DE-PF (*2) management and operation.

*1)DF-PF:Digital Factory Platform

*2)DE-PF:Digital Engineering Platform

We are verifying the standard functions of the software that underlies the platform, linking product data with facility data, and linking other software and systems. We are also performing process verification in some practical cases.

▲Realizing Monozukuri with CPS at the Core

▼Promotion of DX

Manufacturing production DX and plant DX efforts

We are participating in the promotion of DX in the manufacturing process and plant logistics.We continue to take on the challenge of contributing to manufacturing innovations and solving customer issues by proposing solutions that leverage TPEC's strengths in "digital-based manufacturing."

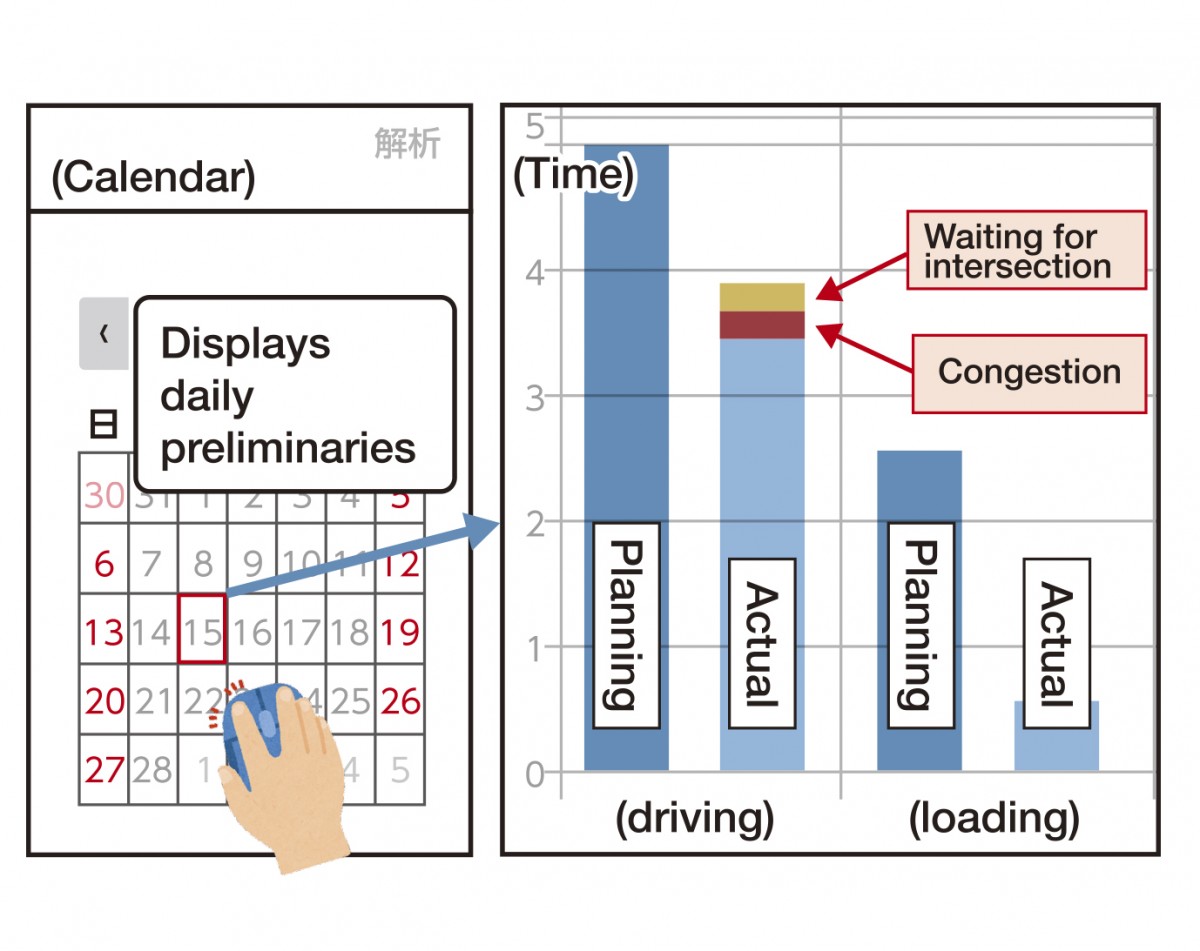

【Support for establishment of factory forecast management system】

Participating in the development of apps and the construction of systems utilizing them.