DIGITAL T-time

DIGITAL T-time

Business Report for the 34th Fiscal Year

●The 34th Annual General Meeting of Shareholders was held

The 34th Annual General Meeting of Shareholders was held on June 20 at the Toyota-Kotobuki office.After the meeting, the directors and chief officers visited the 'Inheritance and Evolution Village' at Toyota Motor Corporation's Honsha Plant. They visited the Komatsu 700t press machine, which returned from Brazil for the first time in 60 years, and experienced the determination and challenges of our predecessors at this special place, which can be said to be the starting point of TOYOTA. It was an opportunity for TPEC to pledge once again to contribute to "better car manufacturing.

●Business Report for the 34th Fiscal Year (April 2024 - March 2025)(excerpts)

●Health Management

The company's strategic approach to employee health management from a managerial perspective was highly evaluated, and it was selected as one of the “Excellent Health Management Corporation 2025 (White 500),” corporations, which is a certification system for corporations.(This is the 8th time in total that the company has been certified.)

●Creating a climate

A study session for managers was held as part of efforts to achieve zero harassment. Inviting a lawyer as a lecturer, participants deepened their understanding through explanations using specific examples and an interactive question-and-answer session.

●Support for Diverse Work Styles

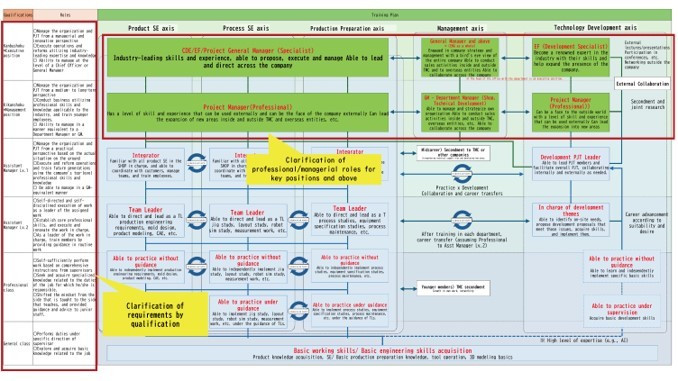

Toward the future vision, we have reviewed the company-wide career map and clarified the career image of professional personnel and the role of their qualifications, thereby unifying the company-wide sense of levels (see figure below). Individual career plans are being formulated based on this map.

●Support for BEV projects

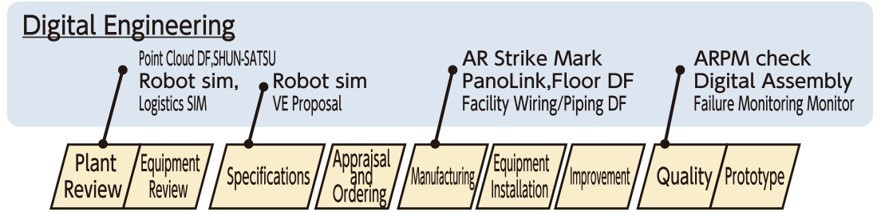

Support for BEV battery production preparation using digital engineering

In the BEV battery case/pack production preparation support, efficient placement of robots using robot review technology reduced the process area and the accompanying transfer time.

We have contributed to productivity improvement by utilizing DE technology (see the figure below), such as reducing man-hours required for checking welding dots by ARPM(*). In addition, we are promoting standardization of specifications with a view to global deployment.

*AR technology with projection mapping

●Toward process reform

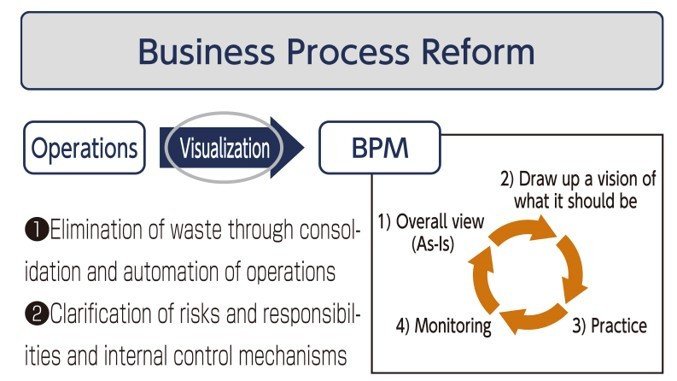

Aiming to reform business processes throughout the entire process, we unified the process charts, which varied among departments, while utilizing the ISO-compliant BPMN(*) method.

Visualization and improvement of 17 processes were promoted.

*Business Process Model and Notation

●Develop and build DE-PF

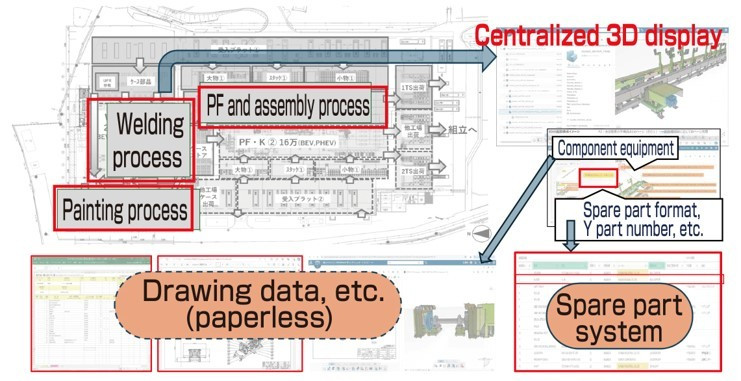

Conservation DX support activities

As part of a system construction project at a manufacturing site, we were involved in building a centralized system for maintenance information in the battery process. We promoted the creation of a system that enables the use of information on related books and spare parts in addition to list information on equipment, including 3D data, for each process.

●Development based on production preparation and manufacturing site

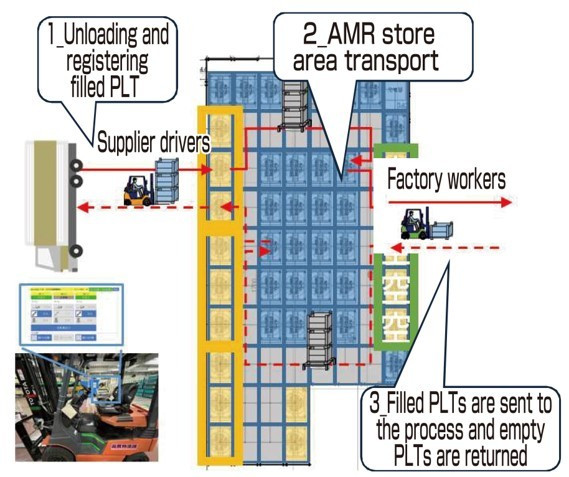

Support for automation of factory logistics

Toyota Motor Corporation's Takaoka Plant has been working to build a free-location store by utilizing AMR (Autonomous Automatic Maneuvering Robot) in the logistics production preparation process (see figure on the right).Through the development of transfer coordinate conversion tools, etc., we are improving operational efficiency and promoting support for the introduction of AMR at each plant.