DIGITAL T-time

DIGITAL T-time

Developing people who can respond autonomously to change

●Plant training for new employees

As part of our new employee training, we conducted three-month factory training at the assembly process of Toyota Motor Kyushu Inc.. Through hands-on training, they felt their duties as a member of an automaker and learned about the importance of quality and on-site innovation by experiencing the Toyota Way and TPS. At first, there were times when we had a hard time with the unfamiliar work, but as we learned and grew day by day, when the end of the practical training was approaching, we received feedback from the workplace that you were becoming an asset and I would like you to stay. Aware of the connection between manufacturing sites and TPEC operations, we will continue to take on challenges as a member of TPEC as we take on the future-minded by the learning gained at the sites.

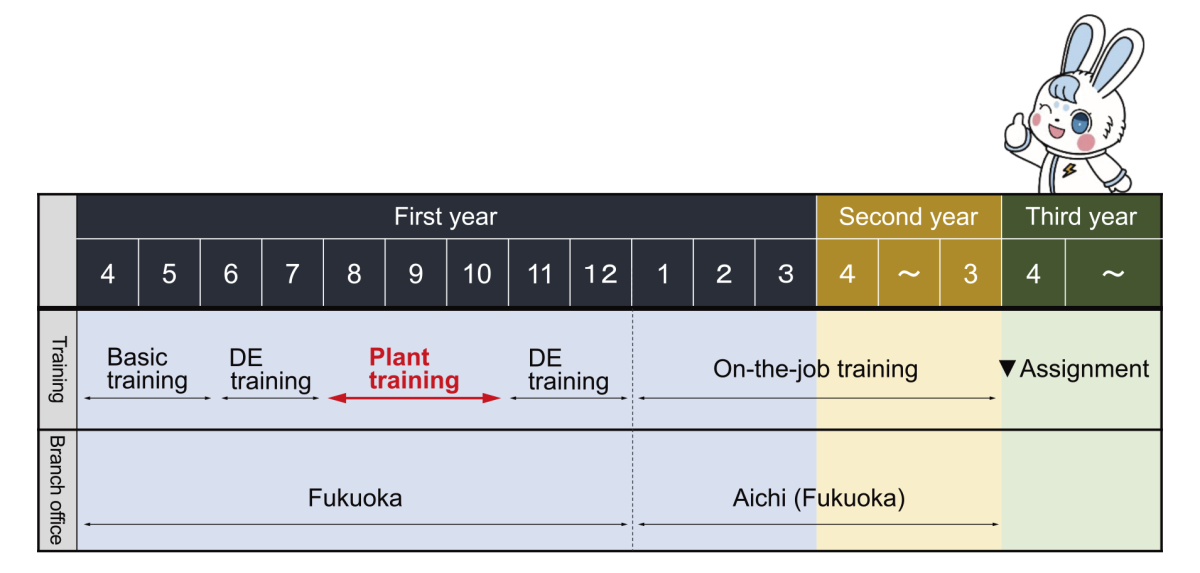

▲Training schedules after joining